danm

Member

Hi, it has been a long time since I posted about any progress on my project, too long to be honest! I have been so busy with work and a dose of pneumonia hasn't helped either, not to mention that my other hobby of stationary engines has been taking up a fair bit of my spare time.

Some significant progress has been made though. Under the bonnet is near enough complete, save for the odd minor detail. I have driven it locally and generally I am very pleased with the installation. Although it is smooth, quieter and has better low speed torque delivery the initial test run highlighted an issue that needs addressing. The car does feel more "pokey" than it was before but not by as much as I was expecting. I have owned DOHC engines before in their correct homes under the bonnets of Sierras so I know how they should perform. Despite it running perfectly, the engine in the Rover just isn't performing as it should and is down on power. After much thought (and Bacardi) it dawned on me that I may not be achieving full throttle............A quick check with my mate holding the pedal on the floor confirmed that I was actually only getting 1/3 opening. Somehow I got my calculations wrong when I made the cable conversion and the system is too low geared, I need to up the pedal ratio to increase the travel. Fortunately, I got my sums right when calculating the ratio of the clutch, that works beautifully with a smooth bite at mid travel

Other than that I have made some progress, the PCM is now mounted inside the glove box..

I have made some plates to retain the bulkhead grommet as it would have surely pulled out every time the glove box was opened.

This is how it now looks under the bonnet.

Another issue that quickly reared its ugly head was gear lever to hand brake lever clash. The Ford lever is canted backwards whereas the Rovers is straight, today I pulled the lever back out so that I can modify it. It will be tricky as the bottom section is plastic so I will have to be careful as to how much heat is used!

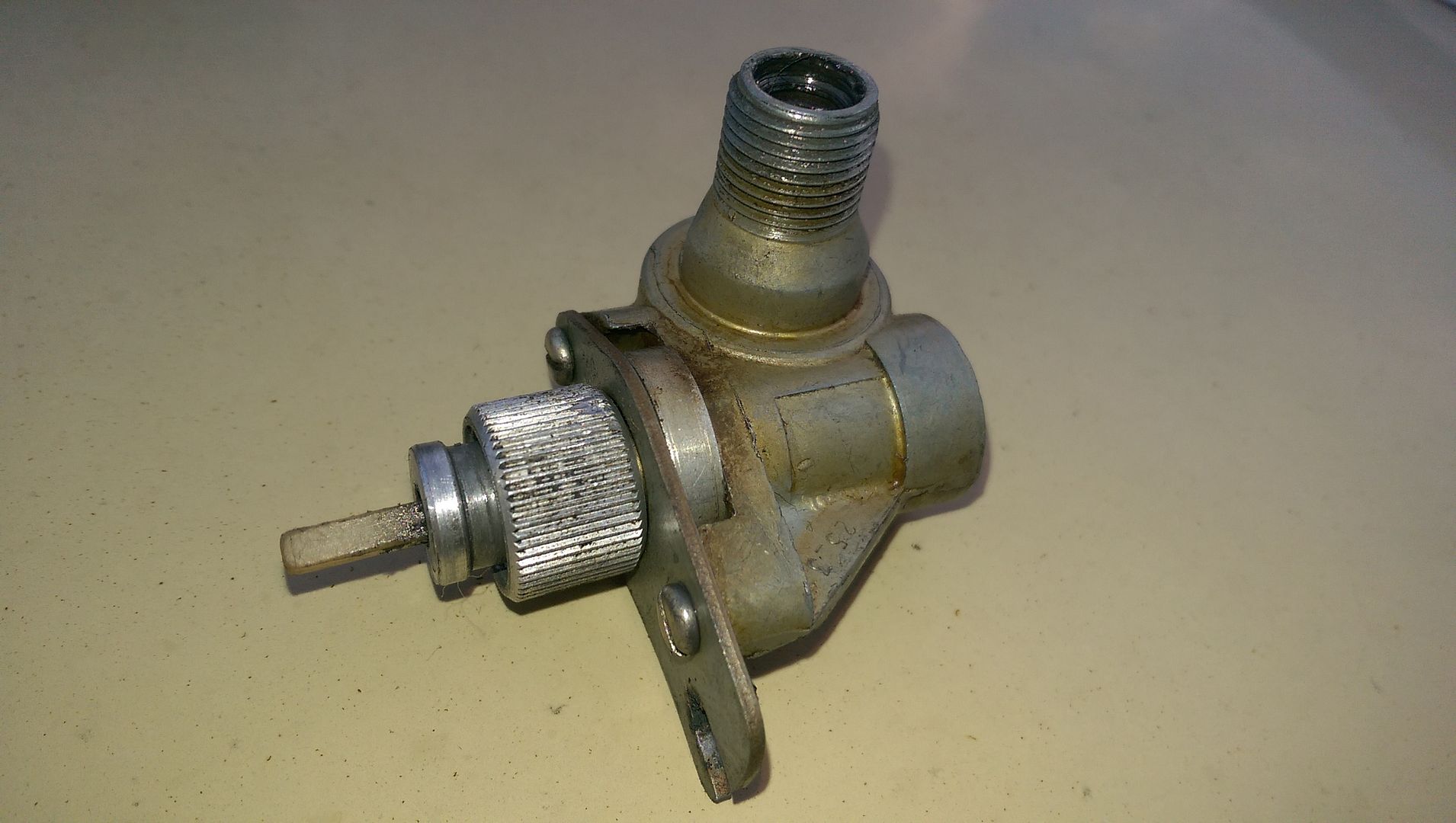

I have also got to make this.......

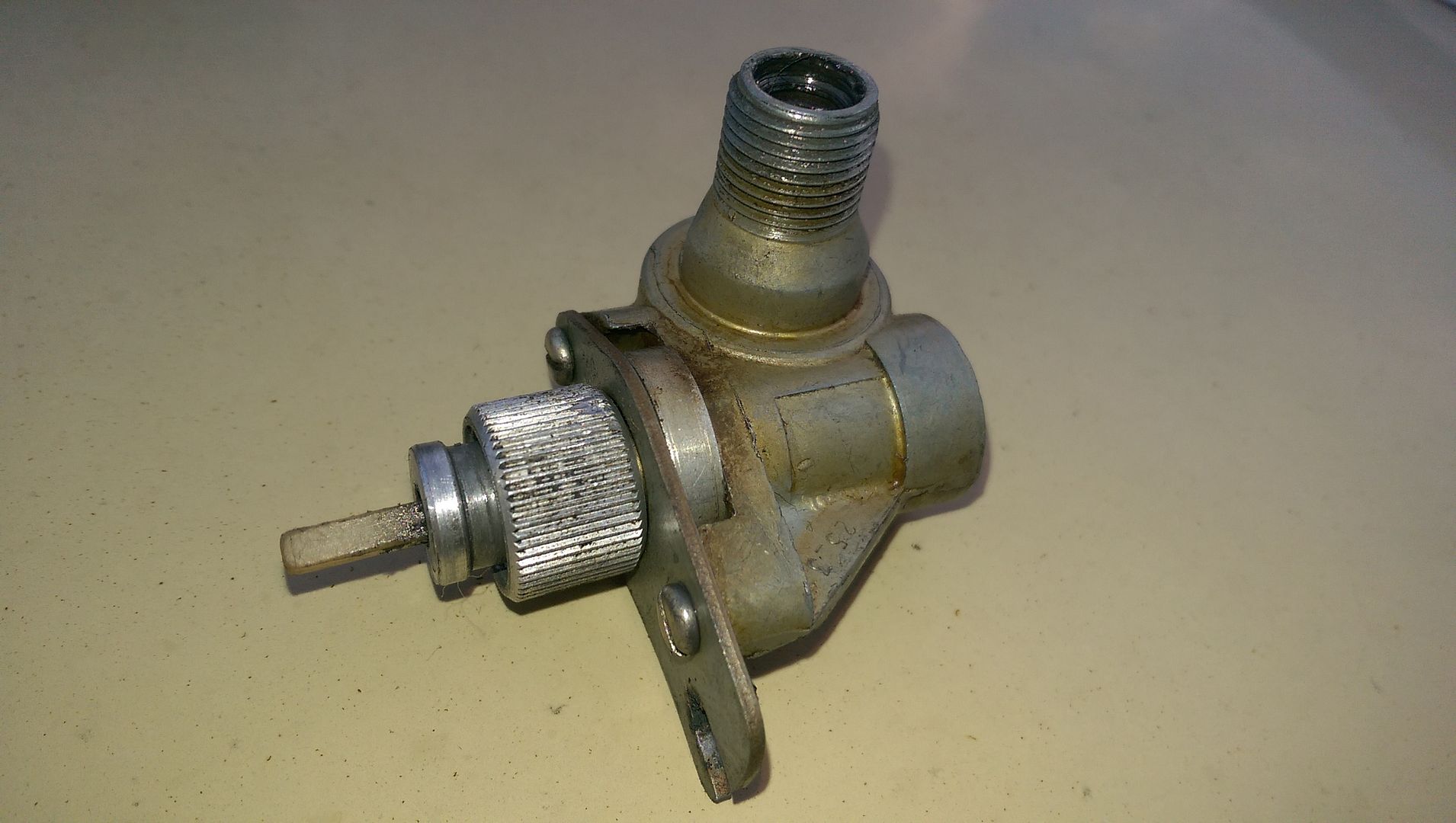

Fit this....

The sierra cable is a little bit too long as well..........

The speedo cable will be interesting as the gearbox and speedometer end require different sized drives, not to mention the odd fitments and lenghts. I am hoping (somewhat optimistically) to get all this done in time for the Battlesbridge show next weekend! :shock:

Dan

Some significant progress has been made though. Under the bonnet is near enough complete, save for the odd minor detail. I have driven it locally and generally I am very pleased with the installation. Although it is smooth, quieter and has better low speed torque delivery the initial test run highlighted an issue that needs addressing. The car does feel more "pokey" than it was before but not by as much as I was expecting. I have owned DOHC engines before in their correct homes under the bonnets of Sierras so I know how they should perform. Despite it running perfectly, the engine in the Rover just isn't performing as it should and is down on power. After much thought (and Bacardi) it dawned on me that I may not be achieving full throttle............A quick check with my mate holding the pedal on the floor confirmed that I was actually only getting 1/3 opening. Somehow I got my calculations wrong when I made the cable conversion and the system is too low geared, I need to up the pedal ratio to increase the travel. Fortunately, I got my sums right when calculating the ratio of the clutch, that works beautifully with a smooth bite at mid travel

Other than that I have made some progress, the PCM is now mounted inside the glove box..

I have made some plates to retain the bulkhead grommet as it would have surely pulled out every time the glove box was opened.

This is how it now looks under the bonnet.

Another issue that quickly reared its ugly head was gear lever to hand brake lever clash. The Ford lever is canted backwards whereas the Rovers is straight, today I pulled the lever back out so that I can modify it. It will be tricky as the bottom section is plastic so I will have to be careful as to how much heat is used!

I have also got to make this.......

Fit this....

The sierra cable is a little bit too long as well..........

The speedo cable will be interesting as the gearbox and speedometer end require different sized drives, not to mention the odd fitments and lenghts. I am hoping (somewhat optimistically) to get all this done in time for the Battlesbridge show next weekend! :shock:

Dan