cobraboy

Well-Known Member

Nice.

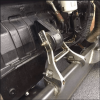

Many, many years ago I bought these mounts as they were all I could find with the reinforcing plate. They have been excellent with no degradation at all. They are advertised as Metalastik, but I doubt they are genuine, mine might well have been though, back then.

Aston Martin DBS V8 and DBS6 Engine & gearbox metalastic mounts, Sold as a pair. | eBay

Many, many years ago I bought these mounts as they were all I could find with the reinforcing plate. They have been excellent with no degradation at all. They are advertised as Metalastik, but I doubt they are genuine, mine might well have been though, back then.

Aston Martin DBS V8 and DBS6 Engine & gearbox metalastic mounts, Sold as a pair. | eBay