Hi guys.

I haven't been able to do anything much to Minstrel over the past 8 weeks or so since I started work in late August. I work 11 hours a day Mon-Fri and the weekend is taken up by shopping and spending time with my wife. Problem now is not shortage of money. More shortage of time. Lol.

I did manage to take the starter motor off today to replace the brushes. About 6 weeks ago my son, Shane, made me a stainless steel water pipe to replace the original rusty one that runs alongside the rocker box to the heater while he was at sea. When we tried to fit it, it was wrong. He could only go by the dimensions I gave him (which were right according to the original pipe!) instead of taking the original pipe back with him as a template. Anyway we refitted the original back on, refilled the rad, connected the battery, turned the key to start Minstrel and............click! Nothing. Thinking the battery was dead we tried the one off Shane's 1990 Mitzi GTO which was fully charged and...........again, click! First thing I said was starter motor jammed. Bendix is not being thrown. So we took it off. I took it down the workshop, cleaned it up and tried it on a battery prior to refitting it. The motor span slowly, but I put that down to possibly a low battery charge. Put it back on the car and tired again. Still only got a click. As I said we took it off this afternoon and stripped it right down. The brushes are pretty good so they didn't need to be replaced (I had bought some just incase). Then we looked at the bearing on the armature. It felt very gritty, so it was soaked for a while and we had another look at it. Still the same. So it looks like the bearing is possibly knackered. I have rung a rewind company in Lowestoft and they said probably around £50-£60 to have the starter repaired. That is if it doesn't need any major part renewed.

The most annoying thing about it is the fact that prior to taking the exhaust and carb off, the starter motor was working just fine. Shows just how fickle these things can be! I looked on eBay on my phone and the only one I could find was £136.00! Am going to look on my laptop tonight as I get a better and more detailed view on there. I don't know if that starter was used on any other vehicles. Perhaps one of you guys could give me more info on that, please?

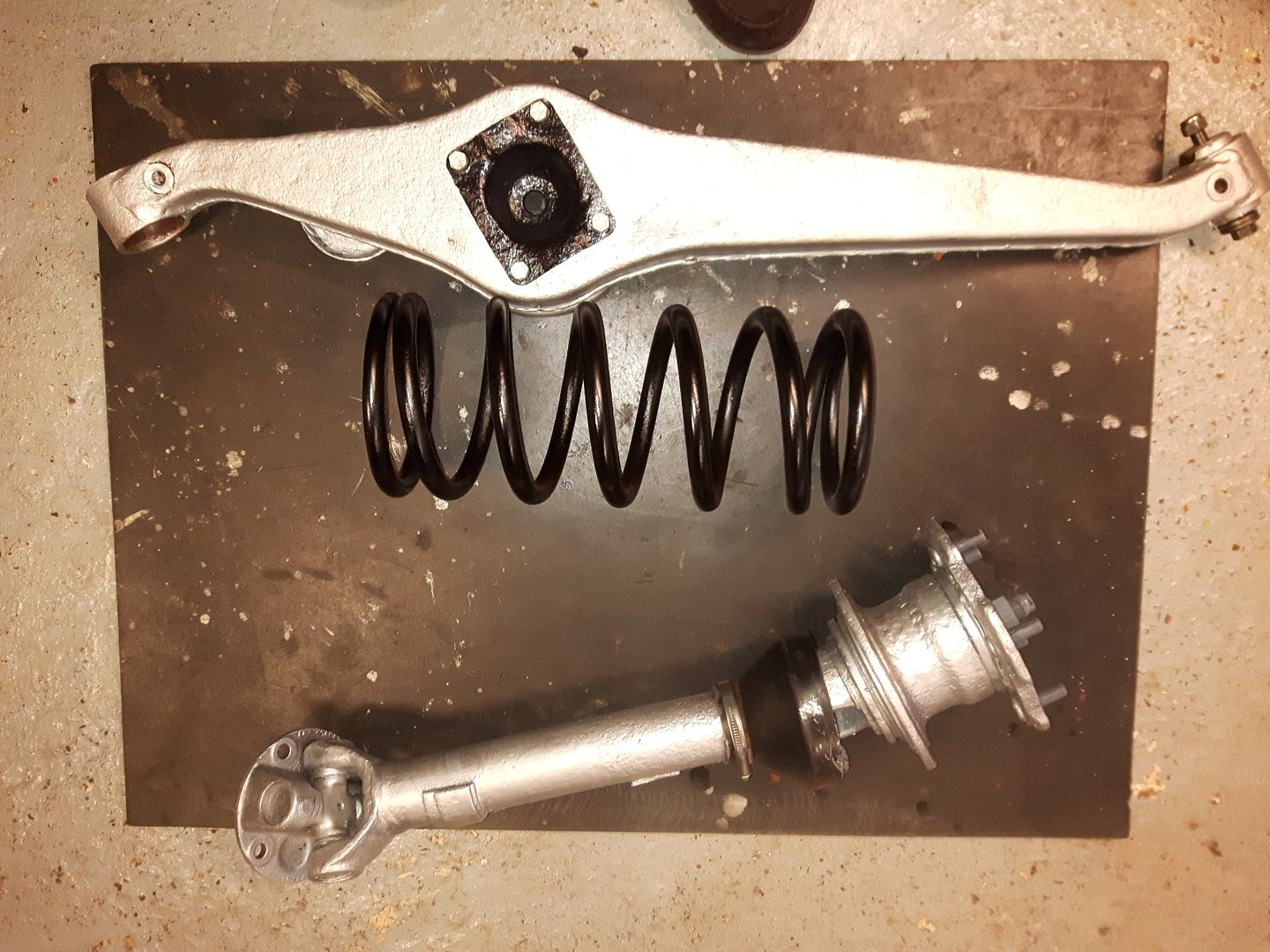

Not done anymore to the rear suspension since the last report. I am seriously going to have to find some time before the bad weather and winter sets in to dismantle and check the nearside.

The only other improvement I have done is to buy Minstrel a decent cover for her for the autumn/winter period as I don't have access to a garage where I could store her. I try to spend a few minutes a week uncovering and recovering her so that the cover doesn't start to stick to the paintwork. Although when I bought the cover the description did state it doesn't damage paintwork. Better safe than sorry!

Will update again when I get a chance to do some work to Minstrel. In the meantime, drive safe and stay on the road.....Steve