Gargo

Active Member

I've started overhauling a very worn engine and thought some of you may enjoy the process. I'll show the old tired stuff, but the focus will be on the new and improved.

Here goes:

The old cam is on the right,

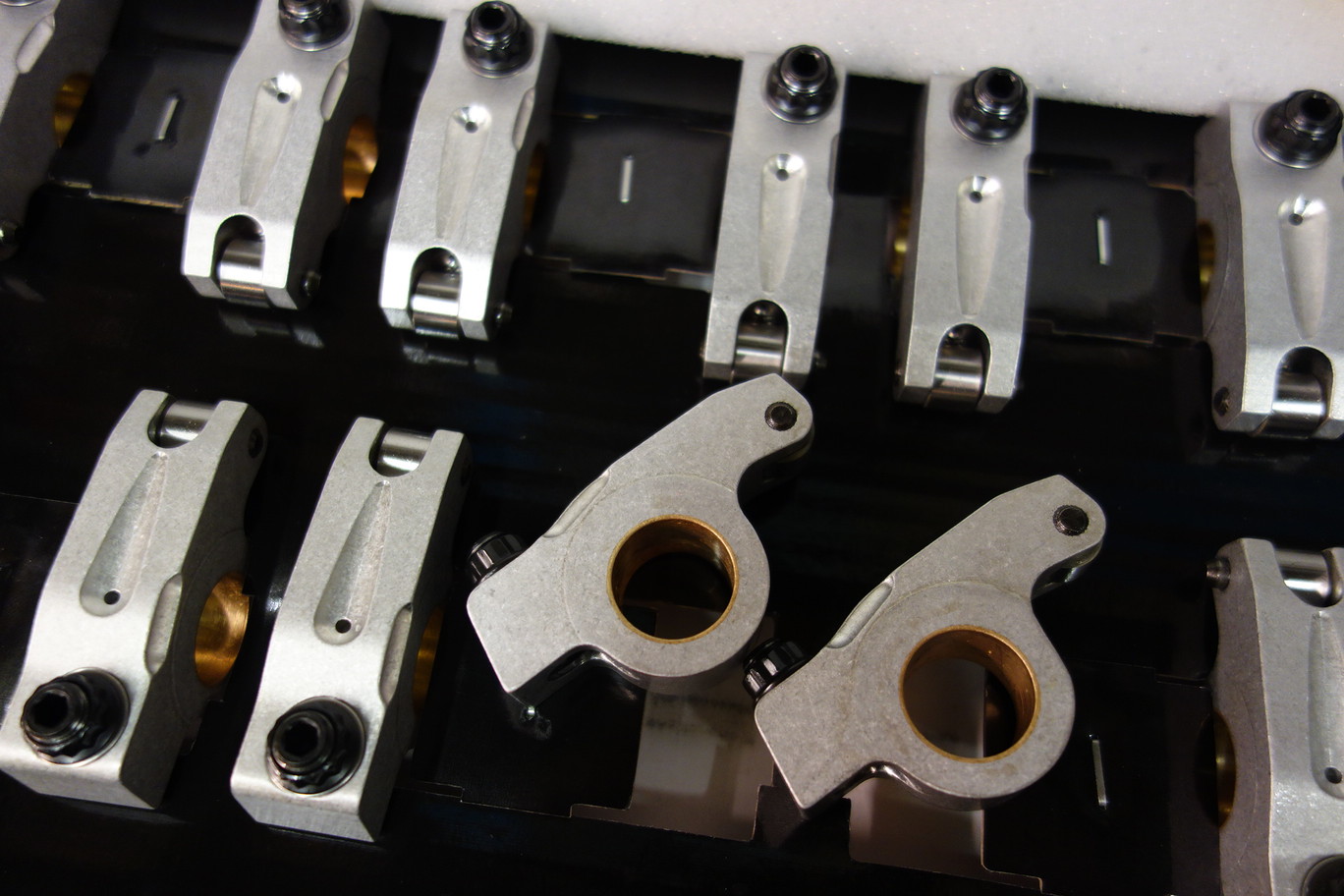

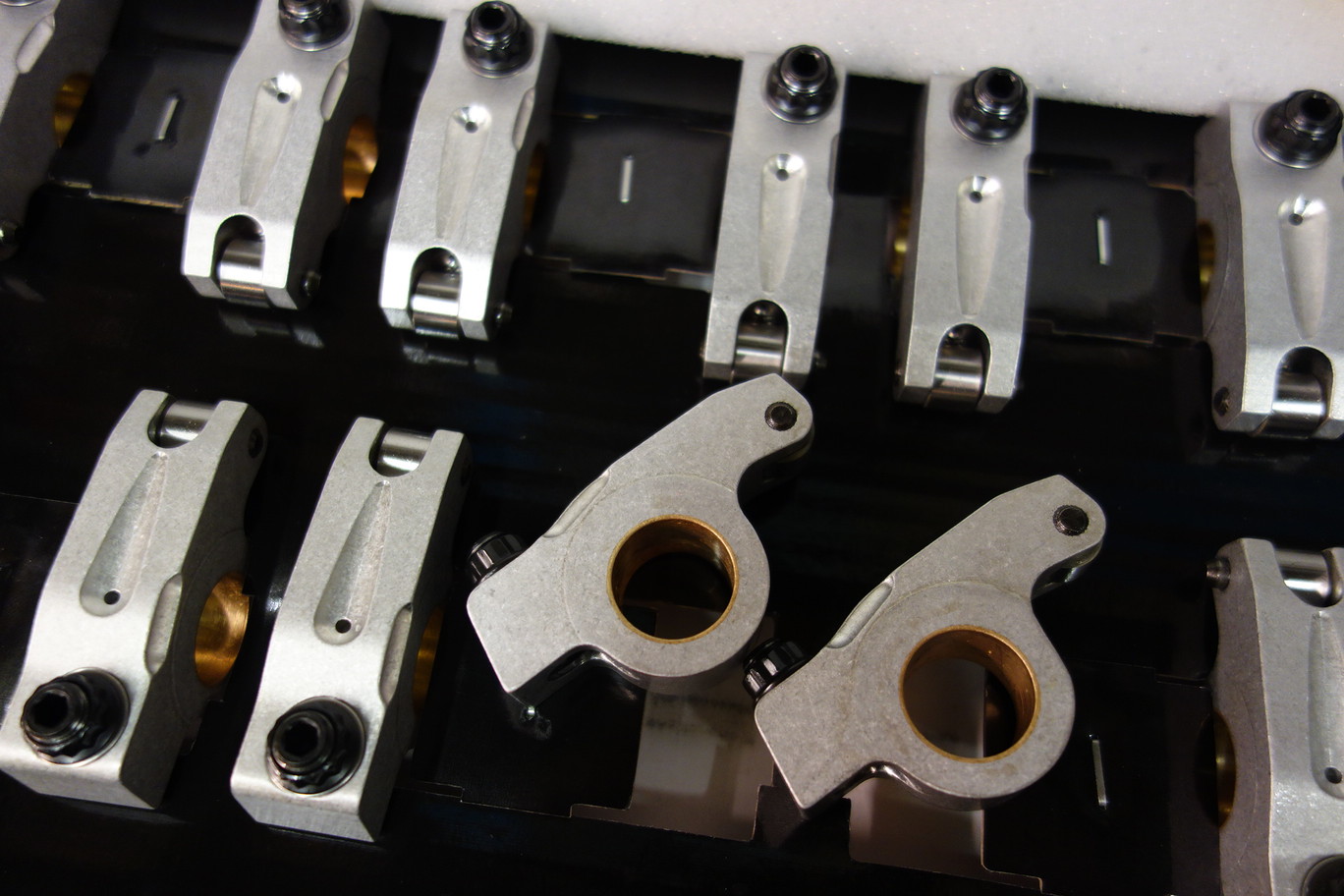

The old cams standard lift of 6.6mm has worn down to 3.8mm on two lobes, only one lobe is giving over 6.0mm of lift!!! It's no wonder why many suggest you renew a standard cam to improve the power of an old engine. The new cam shown here is a little bumper and will push these rockers,

and will push these rockers,

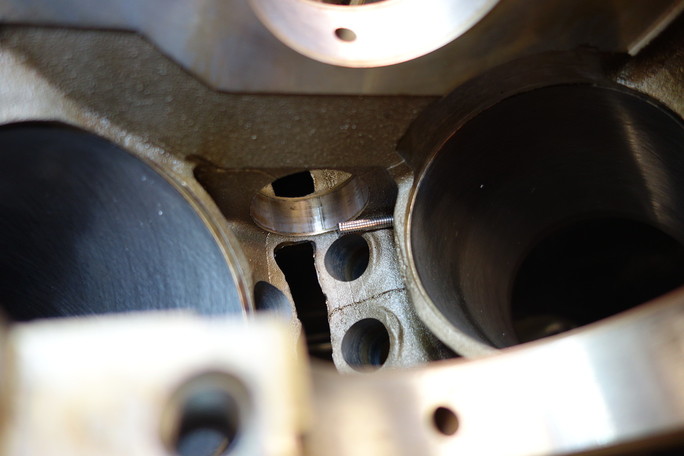

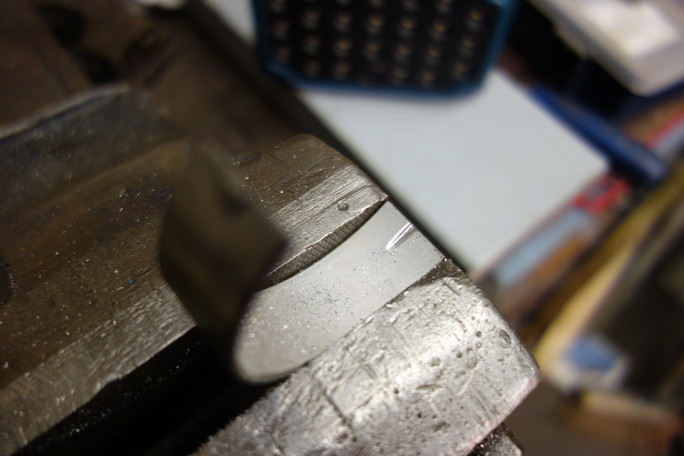

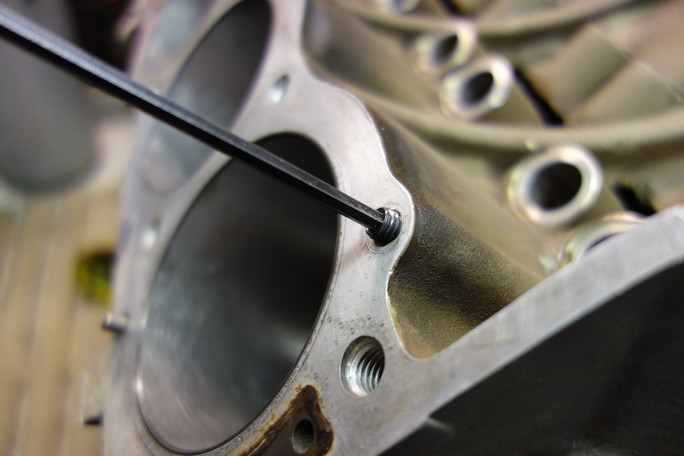

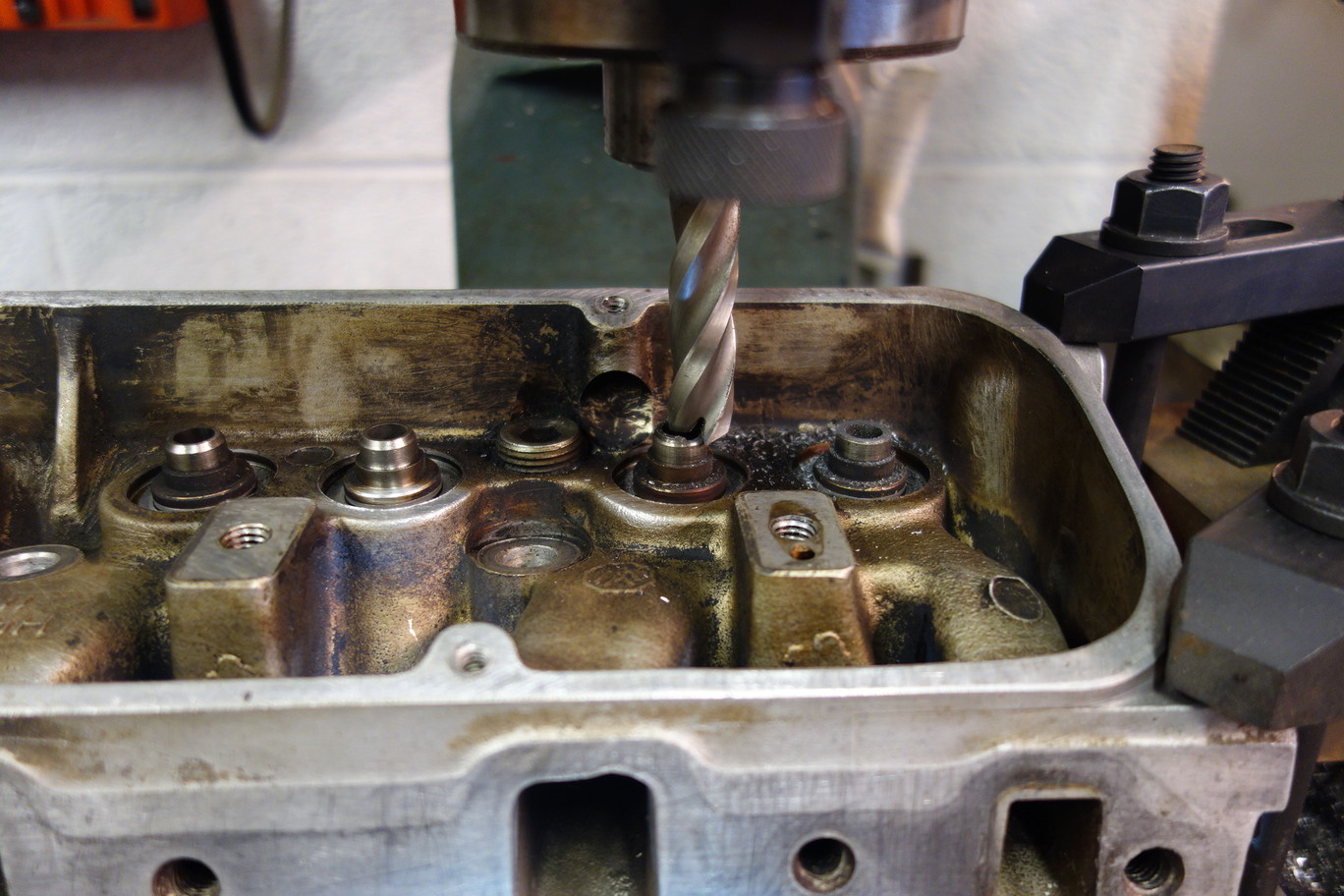

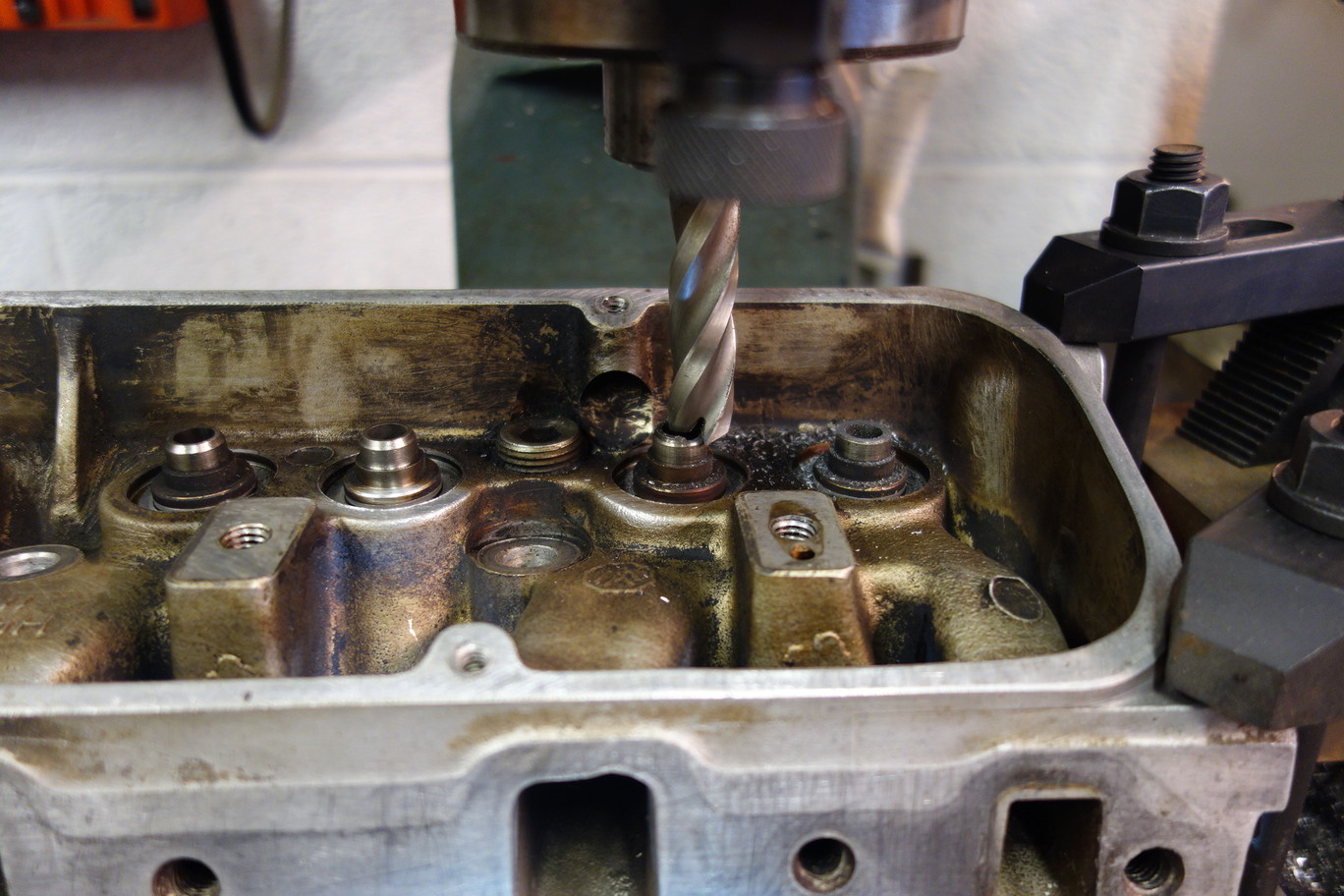

The problem of a bumper cam is that the valve guides are too high and the valve caps hit the valve seals, so you simply move the valve guide seal profile down the guide. Some may push the guides down into the head but this would restrict the gas flow in the ports, so machine the top off the guides.

and re profile

Here goes:

The old cam is on the right,

The old cams standard lift of 6.6mm has worn down to 3.8mm on two lobes, only one lobe is giving over 6.0mm of lift!!! It's no wonder why many suggest you renew a standard cam to improve the power of an old engine. The new cam shown here is a little bumper

The problem of a bumper cam is that the valve guides are too high and the valve caps hit the valve seals, so you simply move the valve guide seal profile down the guide. Some may push the guides down into the head but this would restrict the gas flow in the ports, so machine the top off the guides.

and re profile