I was able to get the points operating but had to pack the adjustment screw with washers, which isnt right.

Then I couldn't get the car to start and ended up knackering the starter.

Managed to get covid and it as taken me a few weeks to get back into it.

I pick up a secondhand starter but the solenoid was faulty so I dropped it off at Prolek who are the only place in Glasgow that refurbishes alternator and starters. I will take my original in and have it refurbished as a spare along the alternator.

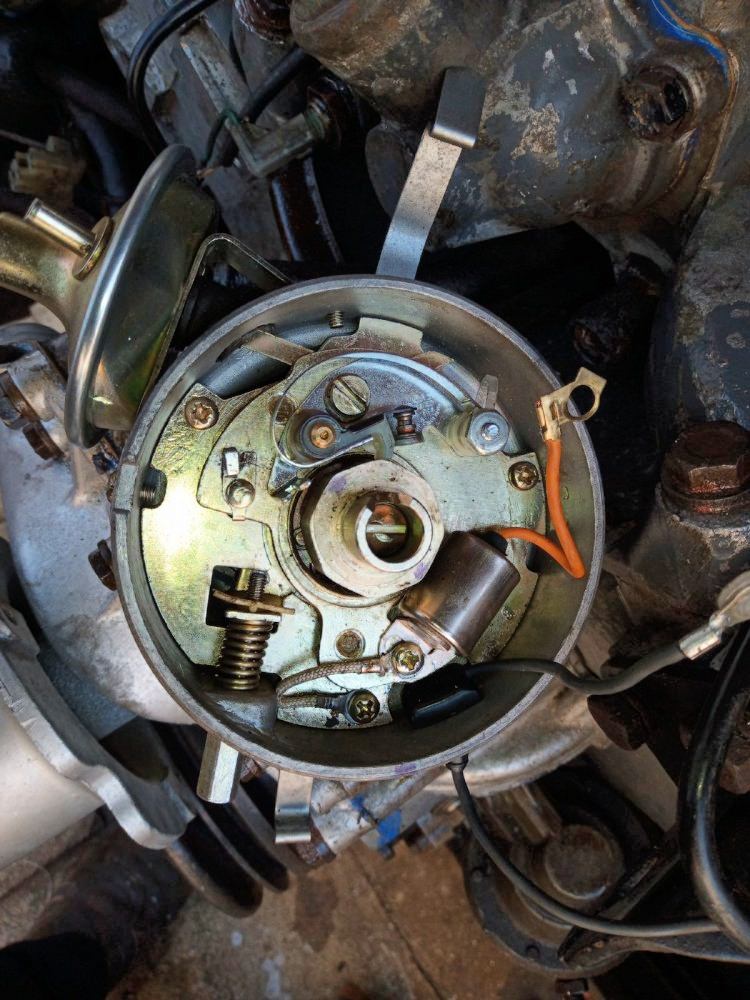

So today I was under the bonnet, fitted the starter and electronic points. I hadn't intended to do it just now but they couldn't get a solenoid cap with the 12v feed to the coil. This wasnt a problem as I told the guy I was converting to a 12v coil. I have powered the coil using the screen washer pump feed for now but will wire it in properly later.

It took a bit of messing about but eventually it fired up. I have rigged up a remote switch which saves having to get an assistant or using questionable methods to activate the starter.

There was a fair bit of smoke coming out of the exhaust but it was the first time in the 6 years I have had it that it has ran and I think the previous owner only briefly ran the engine due to a stuck oil pressure relief valve.

I need to reconnect the cooling system before I run the car for any length of time, also my neighbours bedroom window is near the exhaust so I don't want to be an inconsiderate neighbour.

Glad to have the engine running again, next step will be to get the brakes back on and make new brake pipes. This will mean getting the underseal off and painting the underside which should me managable with the weather changing for the warmer.

remote starter video

The fan blade and PAS bracket have been powder coated, I think the guy did a good job as it would take ages to clean up the bracket. I will spray the other part myself with epoxy.