You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tappet preload with dry lifters ?

- Thread starter mtb_tuli

- Start date

Must admit I do not understand the reference to Tappet preload as I can see no reference in the workshop manual.

An engine in standard specification doesn't need preload adjustment, it only becomes necessary once heads are skimmed beyond factory tolerances, and non-standard valve train components get fitted.

clive P62

Active Member

As Harvey said it shouldn't need doing on a standard engine with just a minimal head reface/ skim and valves not heavily recut.

Ive never checked preload on the many engines I have rebuilt over the years without any noise/running issues.

I don't think the rover workshop manual even mentions preload checking.

If you do want to check it it's done with dry lifters.

Clive.

Ive never checked preload on the many engines I have rebuilt over the years without any noise/running issues.

I don't think the rover workshop manual even mentions preload checking.

If you do want to check it it's done with dry lifters.

Clive.

ratwing

Active Member

You can still check with oil-filled lifters but you MUST wait for the oil to bleed out before measuring.

Although Harvey is right, most of our engines are old now and who knows what a previous owner may have done so I think for the time it takes it's worth checking while they're apart.

Although Harvey is right, most of our engines are old now and who knows what a previous owner may have done so I think for the time it takes it's worth checking while they're apart.

mtb_tuli

Active Member

Man, that´s a fiddling job

Preload is said to be between 0,02" (0,5 mm) and 0,06" (1,5 mm). As each tappet preload is different on one cylinder row, is it more advicable to go more to 0,02 (less load) or more to 0,06 (more load) ?

Then, I have noticed, the tappets were prefilled with oil (bought them new with new cam from a guy who stopped his project). Do they bleed, when I turn the engine manually a few times with the ratchet ? And, maybe silly question, but nowhere explained : when I have set preload, I must take tappets out again to soak in oil, so the tappets will not be in the position again where I have measured and set, or can they be filled when they are built in ?

Preload is said to be between 0,02" (0,5 mm) and 0,06" (1,5 mm). As each tappet preload is different on one cylinder row, is it more advicable to go more to 0,02 (less load) or more to 0,06 (more load) ?

Then, I have noticed, the tappets were prefilled with oil (bought them new with new cam from a guy who stopped his project). Do they bleed, when I turn the engine manually a few times with the ratchet ? And, maybe silly question, but nowhere explained : when I have set preload, I must take tappets out again to soak in oil, so the tappets will not be in the position again where I have measured and set, or can they be filled when they are built in ?

mikecoombs

Active Member

Pre load on a normal rover engine is pretty well non-adjustable. There can be over 1mm of wear in the system and it will automatically take it up. That is the whole point of Hydraulic lifters - no adjustment needed. If you do want to adjust them the only workable way is to shim ALL the pedestals as otherwise you will bending the shafts.

If the engine turns over by hand without the valves hitting the pistons when there is fluid in the lifters you should be safe to run the thing. It does normally take some time to get the last tappet to stop clacking though. It can be over an hour in some cases but eventually it should fill and go quiet.

If the engine turns over by hand without the valves hitting the pistons when there is fluid in the lifters you should be safe to run the thing. It does normally take some time to get the last tappet to stop clacking though. It can be over an hour in some cases but eventually it should fill and go quiet.

mtb_tuli

Active Member

Mike, thanks, but I had skimmed my heads (-0,6 mm) and still using the steel gasket. Preload now was out of the range (over 0,06") and I have a shim set from Real Steel. Real Steel supplies a manual with it but only says, preload between this and that and no information to the other questions I had (which might be nuts).

I do not want to open the engine again, say, for the next months

I do not want to open the engine again, say, for the next months

roverp5Bcoupe

Active Member

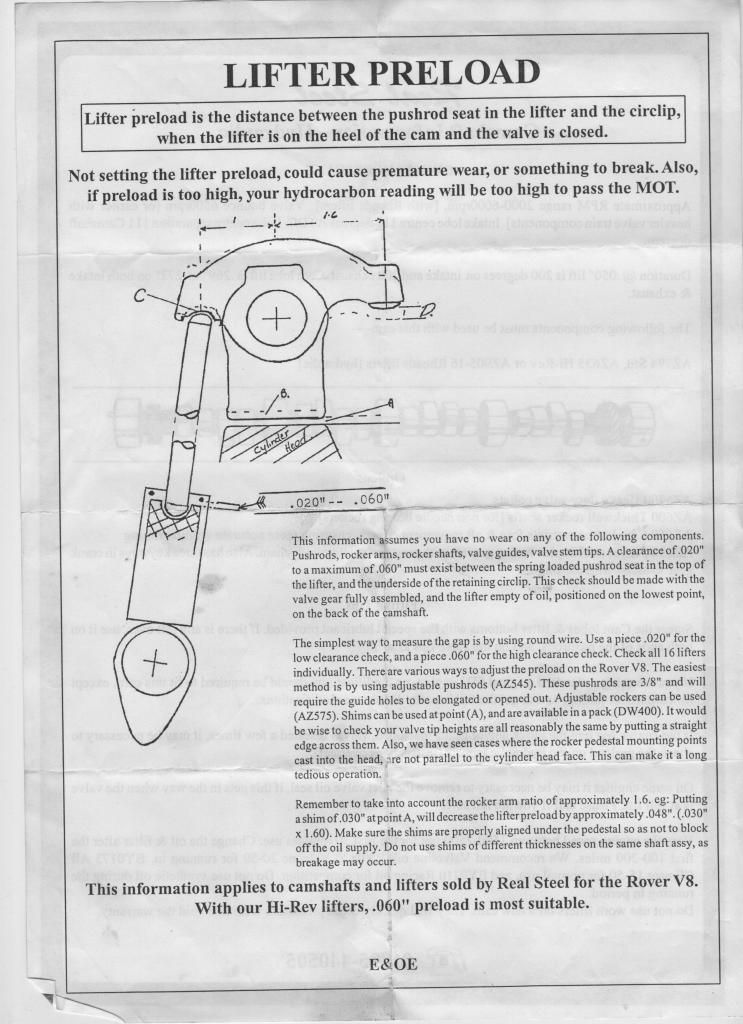

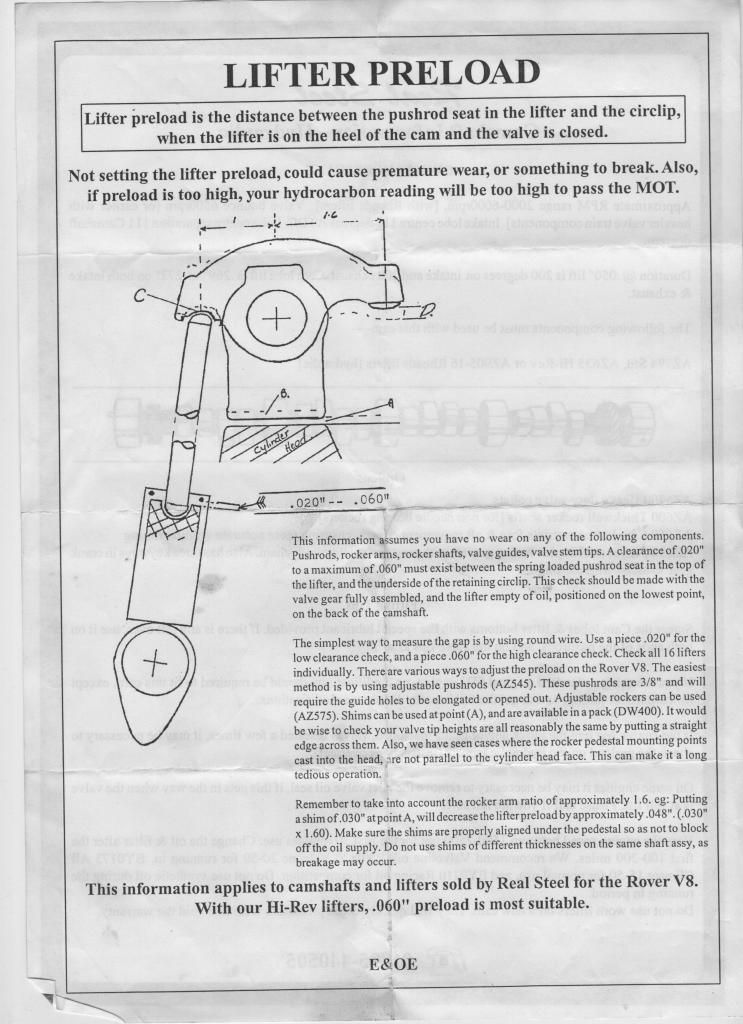

I rebuild a few RV8 and always check the preload and if necessary fit shims to the rocker cover brackets. Here's an instruction how to . Maybe it is not always necessarry but there's not much time or cost involved if the engine is dismantled

mtb_tuli

Active Member

Thanks for it. That´s the manual, I´ve got with the shim set from Real Steel.

But, my lifters are filled with oil from the previous owner (or they get a certain amount of oil when new manufactured, I do not know....). Ratwing said, ok, you can check with filled lifters, but wait until they are bled. But, how are they bled ?

But, my lifters are filled with oil from the previous owner (or they get a certain amount of oil when new manufactured, I do not know....). Ratwing said, ok, you can check with filled lifters, but wait until they are bled. But, how are they bled ?

clive P62

Active Member

Hi you can take them apart and empty out the oil, dead easy. Remove circlip take out middle part and the spring/ drain/ refit.

Mine are new lifters and not oil filled.

New lifters are always noisy even when you soak them first.

Run engine at 2000 rpm for 15mins (remembering to use camlube on cam first when assembling) This runs in new cam and lifters which is very important, by that time any lifter noise should have stopped.

Clive.

Mine are new lifters and not oil filled.

New lifters are always noisy even when you soak them first.

Run engine at 2000 rpm for 15mins (remembering to use camlube on cam first when assembling) This runs in new cam and lifters which is very important, by that time any lifter noise should have stopped.

Clive.

mtb_tuli

Active Member

If you do this the first time, you will finally hate this circlip....

Ok, everything´s back. With 0,4 mm shims some lifters are a little bit over the peak (next size was 0,8 mm), but ok, now it´s getting theoretically...

I had a look on my manual (from Real Steel) again, they changed the settings to a preload of 0,04" to 0,06" !

Ok, everything´s back. With 0,4 mm shims some lifters are a little bit over the peak (next size was 0,8 mm), but ok, now it´s getting theoretically...

I had a look on my manual (from Real Steel) again, they changed the settings to a preload of 0,04" to 0,06" !