Well, we're a bit new to the forum to ask if someone would do us a favour, but you can only say "nope".

Background: Our 'new' Greek export P6 LHD 1971 2000TC is being fettled for a rather 'challenging' rally in 2 weeks time. We have a great local resource, an ex-Rover mechanic (worked in Solihull) that we are relying on, but parts are obviously a problem.

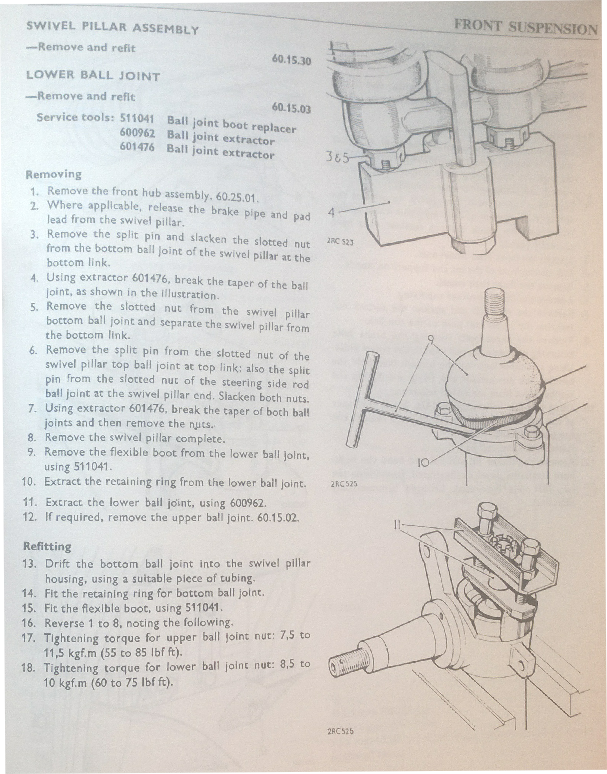

Our Issue: We've just fitted two bottom links to the fronts, which has revealed the need for a replacement RHSF bottom ball joint. Locally, we cant get a bottom ball joint assembly quickly and our local mechanic wont have time to make a bottom joint puller and fit a new one before the rally. Fortunately, I think a mate can bring over ball joint replacements from the UK as he's flying in at the weekend, so we have hope.

Would any kind member either; be willing to lend us a bottom ball joint puller tool by posting it to Yorkshire (all costs plus more will be covered) in the next day or two; or refer us to a club prepared to do similar. We can get it back to the UK by early November latest, with grateful and appropriate thanks.

Being new to the forum I realise that this is cheeky, but here's hoping someone can extend trust (almost) to breaking point.