I am hoping that the pile just recovers on its own when I start using the car again, I will just have to wait and see. Just a few bits I have done over the last week or so.

I managed to get the roof panel to work and took a pic of the underside in case there were any complicated bits and I needed a closer look. Always a good idea to get loads of pics.

I found it quite easy to peel the old vinyl from the roof panel, surprisingly easy in fact. I noticed that there were splits in the cotton scrim under where the marks were. There were also a number of small holes and black marks on the roof in this area. Not sure what caused his but it did look like it was deteriorating.

I cleaned the old adhesive residue off and then rubbed the whole panel down with some wet n dry.

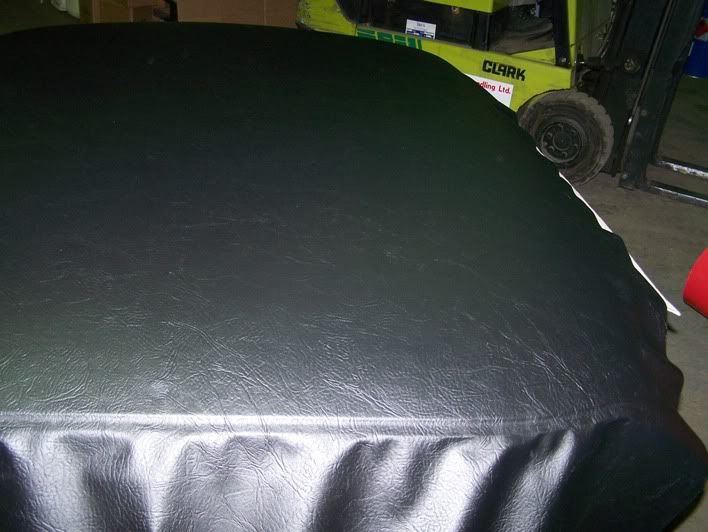

Draping the new vinyl over the roof, I couldn’t work out how it was going to fit over the compound curves.

I had read not to try and stretch it, so braved it and just applied the glue. I used a hand applied high heat contact adhesive and coated the whole of the vinyl in one go, then the whole of the roof. Don’t try to do the roof or vinyl in sections i.e. do the centre third first then fold it back and do the ends afterwards. It doesn’t work

DAMHIK

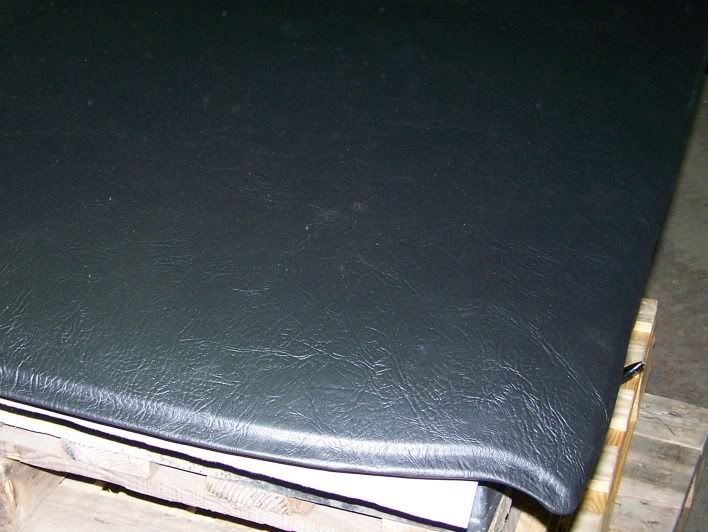

Then up on its side on some packing foam to pull the edges over, and cut out all the little tricky bits.

Took my time with this and got some good definition on the corners.

Then managed to get it home yesterday and just dropped it onto the car.

I had finished the fuel system, pump is now in boot and the reserve switch is up above the diff extension. All connected up and working. Mud flaps on, rear wings back on, rear scuttle adjusted to match up with the boot lid and wings, and car off the ramps. Unfortunately, I had the camera at work so no pics, well except for this one where I had started to fit the reserve switch onto a 2mm plate prior to cutting it up to use as a bracket.

Next job is to seal the roof up and get it bolted down, then.... well…. lots of other stuff

Richard