ghce

Well-Known Member

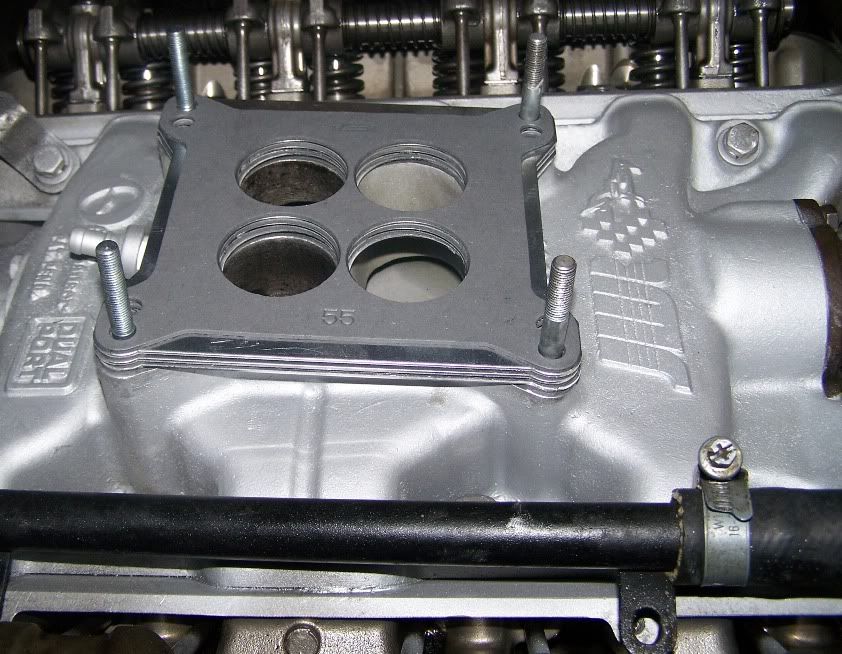

Well I thought I had solved my hard restart problems with my W 500 carb by installing an edelbrock heat insulating gasket as it seemed to be ok and the power had increased when taking off from sitting at the lights when hot as well, no more hesitation. However as the weather has improved I have been taking the car out more and it appears that my earlier prognosis of a cure was not as well founded as I had led myself to beleive  What really has me puzzeled is that the engine has to cool right down (3 or 4 hour) before it will restart not just 30 mis or an hour. The car has an electric pump which I might relocate to somewhere cooler as it's currently in the engine bay mounted close to the washer bottle, so hardly the coolest of environs to live in and maybe I should re rout the fuel line as well? once I have done all that I might have to look seriously at the carb, though I dont know really where to start I cant imagine it's a float level problem really a bit odd with the way the carby or engine has to be cold to restart???? any ideas??? any one????

What really has me puzzeled is that the engine has to cool right down (3 or 4 hour) before it will restart not just 30 mis or an hour. The car has an electric pump which I might relocate to somewhere cooler as it's currently in the engine bay mounted close to the washer bottle, so hardly the coolest of environs to live in and maybe I should re rout the fuel line as well? once I have done all that I might have to look seriously at the carb, though I dont know really where to start I cant imagine it's a float level problem really a bit odd with the way the carby or engine has to be cold to restart???? any ideas??? any one????

Graeme

Graeme