Whilst tarting up the engine recently, I changed the inlet manifold bolts for some nice stainless ones. The rear offside bolt had a strange black goo on it much like a butyl sealant, or the old gum gum type non setting sealant. I have found this substance in various places around the car, including sealing a makeshift gearshift boot to the tunnel, and fixing the fuel pressure gauge into its housing.

A few days ago, a heat dissipator gasket arrived and I set about fitting it. The rear offside bolt holding the carb down was also covered in this black goo

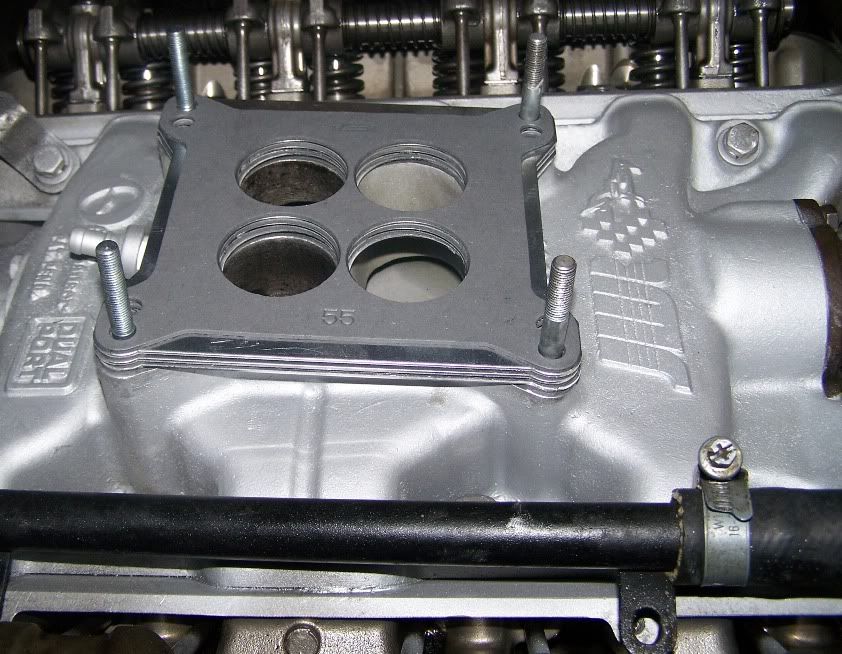

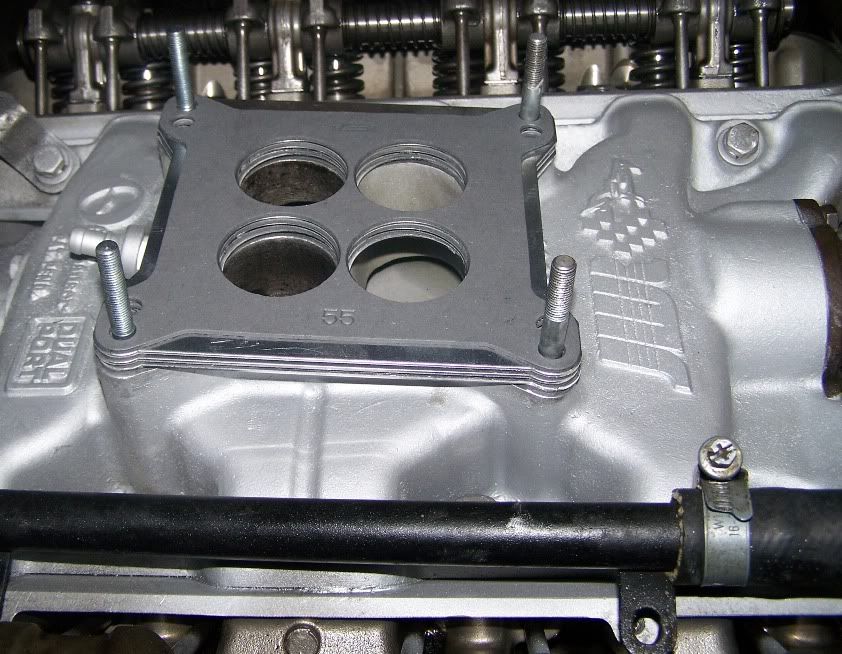

I took the carb off to find that the gasket used was the wrong one. The carb is a four barrel on a twin port mainfold, meaning that the front two feed all 8 cylinders, whilst the rear two feed just 4 each on their own side. They should not be allowed to interfere with each other so a four hole gasket should be used. The gasket pictured is a square hole gasket and does not seal the barrels independently. The angled plate here has another square hole gasket on the other side.

Just as a precaution I took the inlet manifold off as I was concerned about the black substance.

It appears it was just sealing the bolt hole itself as there was no sign of it on the composite gasket, although the waterway at the rear was discoloured slightly. I have to wonder if the sealed off waterway (No access for it in the manifold) was leaking up the bolt hole :?:

All back together now, new valley gasket hylomared in, new heat gasket, in place of the old angled plate (hoping I don't need that), running just a little smoother now and hopefully will be able to tune the fuel system better. I did get hold of a Boach Lambda sensor and fitted it to the nearside manifold when I had the engine apart. Fit that to a gauge and I can get some real time A/F readings very soon.

A few days ago, a heat dissipator gasket arrived and I set about fitting it. The rear offside bolt holding the carb down was also covered in this black goo

I took the carb off to find that the gasket used was the wrong one. The carb is a four barrel on a twin port mainfold, meaning that the front two feed all 8 cylinders, whilst the rear two feed just 4 each on their own side. They should not be allowed to interfere with each other so a four hole gasket should be used. The gasket pictured is a square hole gasket and does not seal the barrels independently. The angled plate here has another square hole gasket on the other side.

Just as a precaution I took the inlet manifold off as I was concerned about the black substance.

It appears it was just sealing the bolt hole itself as there was no sign of it on the composite gasket, although the waterway at the rear was discoloured slightly. I have to wonder if the sealed off waterway (No access for it in the manifold) was leaking up the bolt hole :?:

All back together now, new valley gasket hylomared in, new heat gasket, in place of the old angled plate (hoping I don't need that), running just a little smoother now and hopefully will be able to tune the fuel system better. I did get hold of a Boach Lambda sensor and fitted it to the nearside manifold when I had the engine apart. Fit that to a gauge and I can get some real time A/F readings very soon.