I haven’t done a step by step guide to rebuilding this thing, as I got a bit engrossed in actually doing it. I must say that it is a bit more involved than I first thought, but still within the capabilities of anyone who is methodical in their approach and has some patience and a few tools.

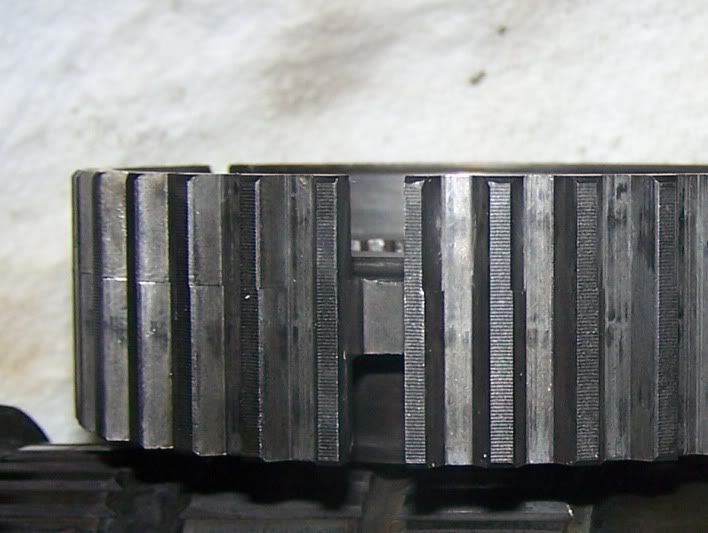

First thing to do is to have a good look around the internet and read up on the internals of the 2WD version of the LT77. I used a manual for a car which had the LT77 fitted, but to be honest it wasn’t much good. If I hadn’t have had the internet, I would have been in trouble. Mainly because, although I was very careful taking things apart and took a load of photos, I still managed to get confused with things like, why are there four synchro rings of one type, and one of another? The one in the pic with the wider lugs is second btw. I don’t know why it has wider lugs?

This synchro hub is not symmetrical and it‘s not in any way obvious which way it goes back on. Of course it’s covered when it’s on the mainshaft so I haven’t got a photo of it in place.

You will need a bearing separator and a selection of pullers to get the old bearings/gears off.

And I still haven’t worked out how to get this pressed in race out of the input shaft, so I had to get violent with it. Manual says, ‘replace bearings if required,’ or words to that effect.

The wear on the top of this synchro hub isn’t actually wear at all, the flats are machined into the hub to stop it from jumping out of third gear, and must face third when reassembling.

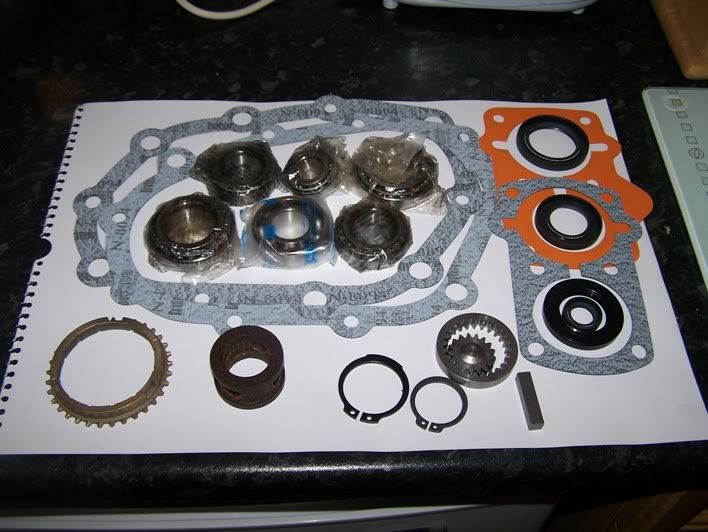

You can buy all of the bits separtately, but I opted for a rebuild kit with Timekin bearings and some extras, which included oil ring, circlip set (the large one doesn’t fit anywhere?, steel oil pump gears, and fourth synchro ring. All that lot came to around £140.00. I could have got away without the bearings as they seemed fine, but thought better of it.

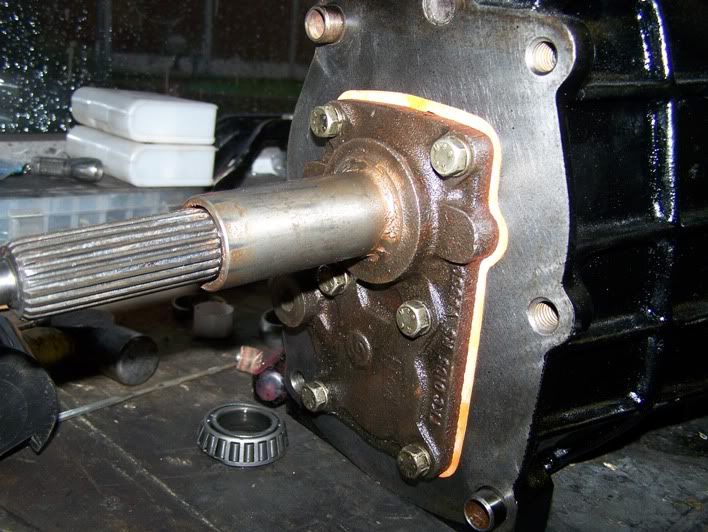

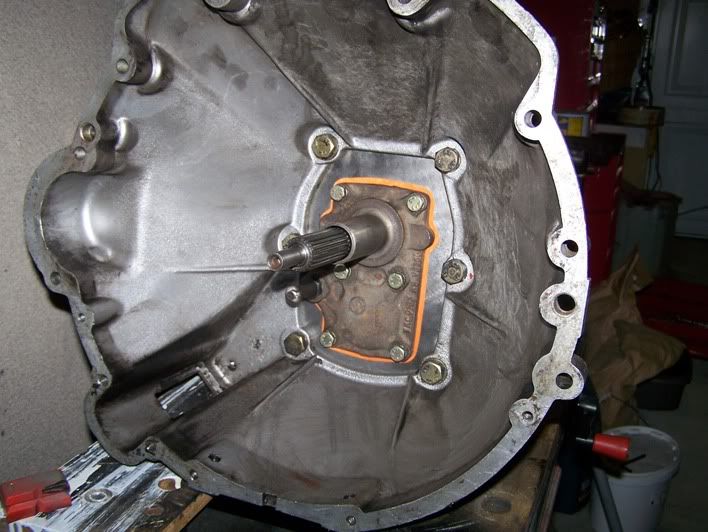

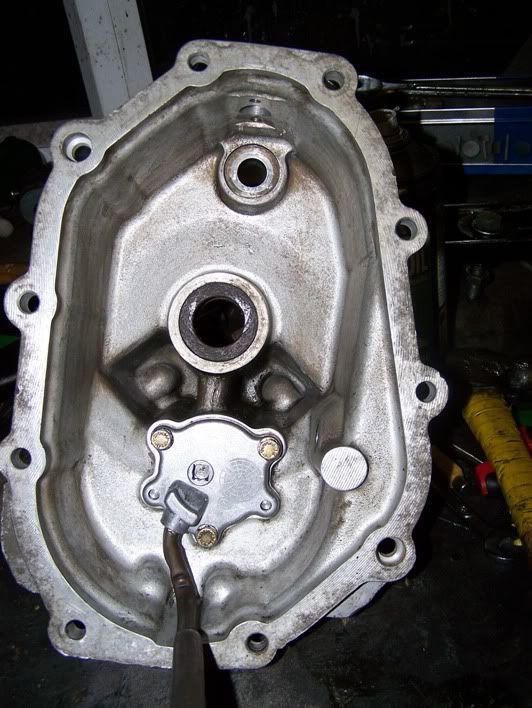

So the front casing is now on and torqued up to enable me to check the end floats of the main and lay shafts. Again, the manual doesn’t mention the actual torque figure so I had to find it on the net. Both the front cover and the bolts holding the front to rear cover (and clamping the centre plate) are 21 lb/ft.

The manual states to remove the third gear first, then first and second. This makes it difficult to remove third as second is in the way. It is a lot easier to remove second/first assembly first i.e. strip the rear of the mainshaft first, as second is bigger than third and can be pulled off without fouling second. I wonder if that makes sense?

The manual also says that after sorting end floats, to remove the slave bolts before reinstalling five gear. I am not sure why it says this as you are going to be trying to press the fifth gear assembly onto the mainshaft with a floppy centre plate, so I will be ignoring that bit, bolting the bellhousing on and having a stable platform to refit the rear end.

We’ll see how that goes. I am still waiting for the new oil pump cover to arrive, then it’s back together and pop it back in.