I am about to rewire the headlights on Sparky.

Currently (no pun intended :roll: ) he is fitted with 55W halogens which don't always work. I have checked the voltage at the headlights and found it to be between 11.6V and 12.2V, depending on where I test it. I can only assume that there is a voltage drop at some or all of the connections along the way, and that the halogens need a full 12V or more to work.

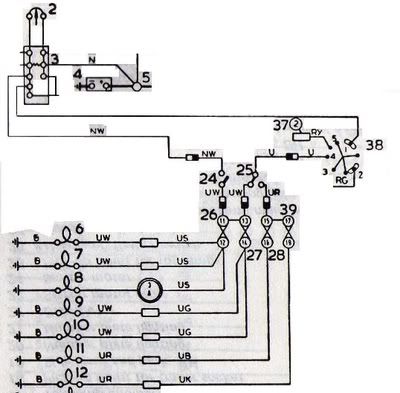

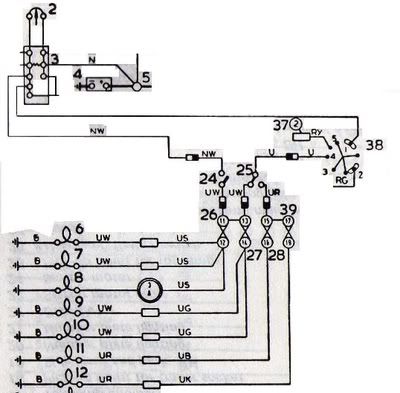

Now, there are two Brown/Wires coming directly from the shunt to the light switch and the headlamp flash. I am intending to connect the one to the light switch to a heavy duty connector and run wires out to 1/. the switch, 2/. 2 relays behind the O/S light and 3/. 2 relays behind the N/S lights. These (2 & 3) will supply the main power to the relays for all of the lights.

I will then fire the relays with the original wiring, i.e.

Relay 1 will be switched on with fuse 11/12 which originally turned on the inner main beams. It will run inner and outer main beams on the O/S.

Relay 2 will be switched on with fuse 15/16 which originally turned on the O/S dip beam. It will run O/S Dip Beam.

Relay 3 will be switched on with fuse 13/14 which originally turned on the outer main beams. It will run inner and outer main beams on the N/S.

Relay 4 will be switched on with fuse 17/18 which originally turned on the N/S dip beam. It will run N/S Dip Beam.

This way, the main power goes straight to the relay and into the headlights without having to go to the light switch, headlamp flash, dip switch, fuse box or the multitude of connectors on the way. The fuse box no longer gets overheating issues as it is only running the relays now. The relays have their own fuses.

I have bought some 2mm auto cable which will handle 25A or 300W at 12V, but now it has arrived, it looks smaller than the original wires! The original wires are only handing one main beam but this will have to take two of them.

Now, am I missing something with this wire? should I have 3mm or 4mm, or is the 2mm ok?

I don't want to have overheating issues with my cure for the overheating issues :shock:

Richard

Currently (no pun intended :roll: ) he is fitted with 55W halogens which don't always work. I have checked the voltage at the headlights and found it to be between 11.6V and 12.2V, depending on where I test it. I can only assume that there is a voltage drop at some or all of the connections along the way, and that the halogens need a full 12V or more to work.

Now, there are two Brown/Wires coming directly from the shunt to the light switch and the headlamp flash. I am intending to connect the one to the light switch to a heavy duty connector and run wires out to 1/. the switch, 2/. 2 relays behind the O/S light and 3/. 2 relays behind the N/S lights. These (2 & 3) will supply the main power to the relays for all of the lights.

I will then fire the relays with the original wiring, i.e.

Relay 1 will be switched on with fuse 11/12 which originally turned on the inner main beams. It will run inner and outer main beams on the O/S.

Relay 2 will be switched on with fuse 15/16 which originally turned on the O/S dip beam. It will run O/S Dip Beam.

Relay 3 will be switched on with fuse 13/14 which originally turned on the outer main beams. It will run inner and outer main beams on the N/S.

Relay 4 will be switched on with fuse 17/18 which originally turned on the N/S dip beam. It will run N/S Dip Beam.

This way, the main power goes straight to the relay and into the headlights without having to go to the light switch, headlamp flash, dip switch, fuse box or the multitude of connectors on the way. The fuse box no longer gets overheating issues as it is only running the relays now. The relays have their own fuses.

I have bought some 2mm auto cable which will handle 25A or 300W at 12V, but now it has arrived, it looks smaller than the original wires! The original wires are only handing one main beam but this will have to take two of them.

Now, am I missing something with this wire? should I have 3mm or 4mm, or is the 2mm ok?

I don't want to have overheating issues with my cure for the overheating issues :shock:

Richard