I had a very interesting day visiting Reg Mason in Birmingham today. Amongst other things we discussed injected P6's and had a good read of this thread. Reg is hopping mad he didn't spot this manifold on Ebay before Kiwi-Rover bought it! I don't think Reg would mind if I describe him as a Solihul insider. His links are with the service side, but in late Range-Rover Classic early P38 period. At that time he was reliably informed that injected P6's in the plural made it to the USA for trials and workshop training. This supports the contention that a Series 2 NADA was intended and nearly produced.

Reg's infamous car - discussed earlier on here - was indeed a factory car. It was still owned by the factory at the time Reg acquired it. It had been stolen from Solihull many years earlier and abandoned by the T Leafs in a field. Rover had never recovered it and its existance was gradually forgotten until Reg came to hear of it. At that time it was very far gone even by P6 standards. The infamous "Lucas Injection" badges were lying separate to the car, as there was no longer anything related to ferrous oxide to maintain their link with the car! As found the car was an automatic base unit with dual circuit brakes, factory A/C and trimmed to NADA spec, but with a manual gearbox and right hand drive. This sounds to me like a prototype S2 NADA that had been converted for use in the UK, perhaps as a gearbox mule prior to release of the UK 3500S.

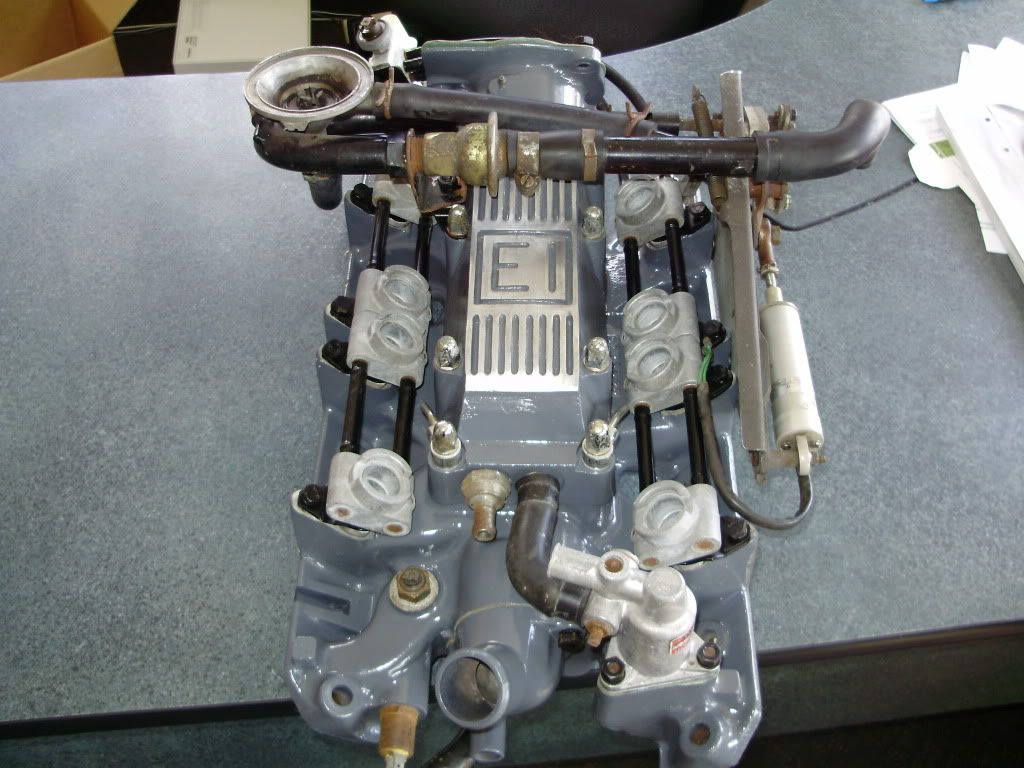

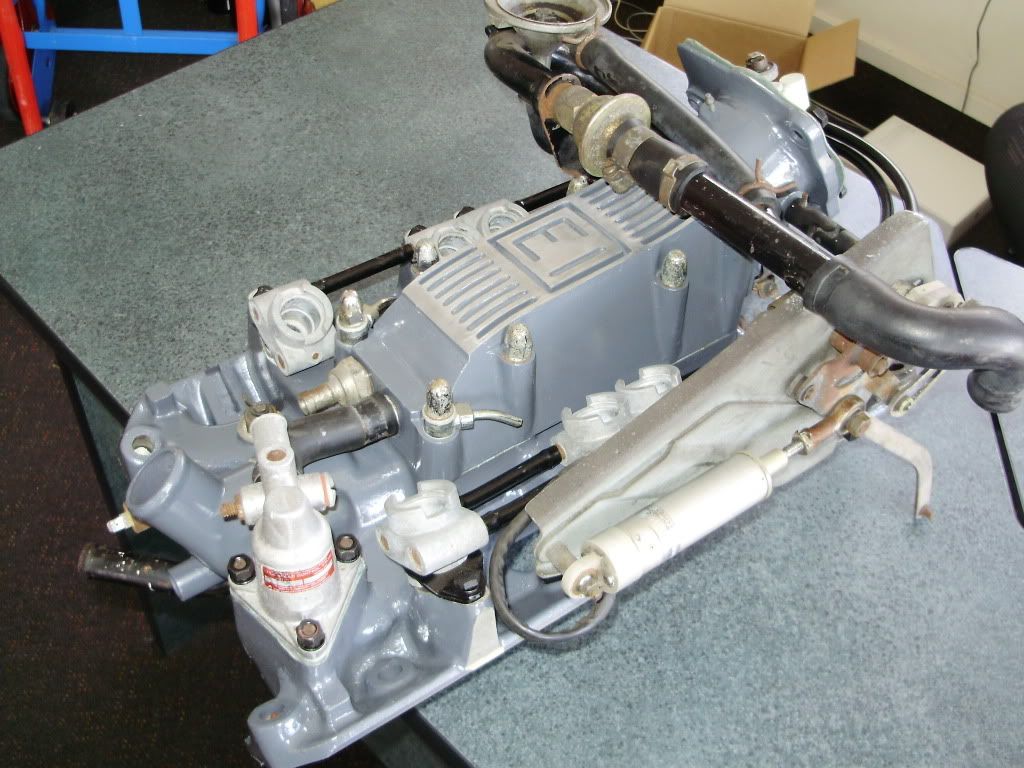

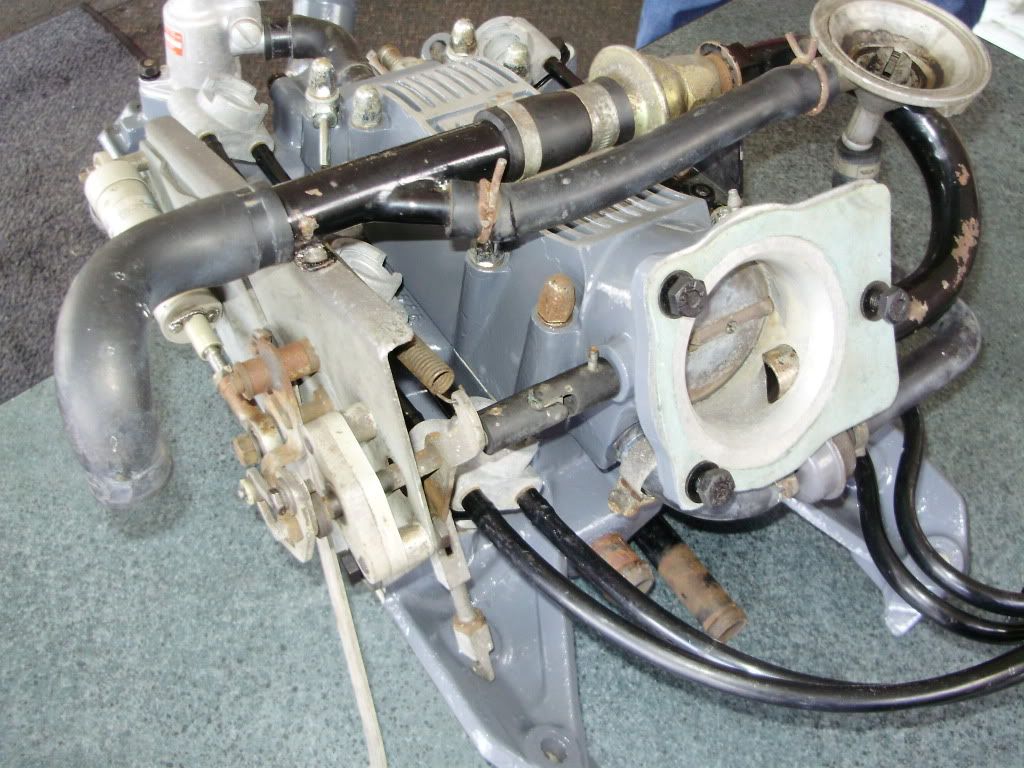

Reg had only ever heard previously of injected P6's in the context of Lucas Injection. He supported this by producing a Plenum chamber from this type of injection, pictured below. From the top it is superficially of a family with the later Range-Rover 3.9 injection with which we are all familiar. But the throttle butterfly intake is on the drivers side instead of the passengers. Underneath you can see that the separation into 8 individual intake tracts has happened in the plenum, leading to 8 in line vents, aligned for and aft, to feed down into the inlet manuifold. And the plenum is very flat, with very little space for the air to be sorted out into the 8 distinct streams. It's no surprise, therefore, that this injection was remebered as being "not very good" (translate into engineering speak at your own risk!). It did re-emerge to production after P6 to be fitted to US market SD1's in 1980. So it ought to be feasible to obtain a set for comparison!

So now we can propose a sequence of events at Rover, which I am 99% certain is accurate. From 1966, Rovr had been working on fuel injection with a number of different suppliers. This was fairly quickly narrowed down to the Brico system. But Lucas continued to develop their own for customers other than Rover. The Brico system was approaching fruition, to the extent that marketing were busy devising model names and badges. Production and launch appears to have been scheduled for Atumn 1970 along with the home market S2 body revisions. But just prior to launch, Lucas bought Brico's parent company Associated Engineering. My suspicion is that Lucas did this to acquire their aerospace and automotive braking technologies. Faced with owning two equivalent and competing injection systems, Lucas pulled the Brico system, leaving Rover's S2 launch missing both the 2000EI and the 3500EI. The US programme was also in dissaray, as both the 4 cyl and the V8 would have had Brico injection there as well. The USA four cylinder went ahead with carburettors as the S2 Federal TC. But with the history of the auto choke on the S1 NADA, carrying over the carburettor V8 to an S2 NADA 3500 wasn't an option, and this model lapsed pending a replacement injection system.

Lucas now had a serious problem. Pulling a major customer's model launch at the last moment isn't known for producing smooth relationships. So Lucas would have been under huge pressure to produce a system, for the V8 at least, ASAP. Hence the system pictured here. There would then have been a second set of prototypes for the Lucas injection and some new badges to celebrate (!) the Lucas association. If, as reported, the system wasn't very good - and I see no reason to doubt this, as it was a) produced in a rush, and b) it looks a singularely unpromising design - then perhaps field reports from the US were negative. Combine this with knowledge of the poor quality of the US dealer network and the fact that carburretored cars were selling just fine in Europe and I can well imagine the bean counters pushing Rover into dropping the whole injection idea and withdrawing from the US altogether.

So I am confirmed in the belief that both the 3500EI and 3500S (Lucxas Injection) badges are genuine. Just that they are around a year apart, with the EI coming (or rather not coming) first and the 3500S Lucas Injection following as a replacement.

Chris