You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Anti Roll Bar- Cheap opportunity!

- Thread starter corazon

- Start date

vaultsman

Well-Known Member

Dangermouse said:Having read all this right through, in my humble opinion, as an engineer, it wont make hardly any difference with a few mill thicker bar. Especially with thinner hex ends. It will just put more twist into the ends, which will fail, quite soon. To make any difference on such a heavy loaded torsional force, you would have to at least double the thickness. So my answer is no its not worth over £100 for a flawed design. which will be prone to failing.

Also in my humble opinion, as an engineer, I would expect to see some calculations to back up your view. :?: :roll:

The stiffness of an ARB varies not linearly with the diameter, but with the fourth power of the diameter. So " a few mill thicker" will have a rather more marked effect than you appear to consider.

In addition, the ends of the trial bar are not thinner, but of exactly the same size as the original. And these ends are clamped in shaped mounts that are, of necessity, larger than the bar ends.

Some numbers:

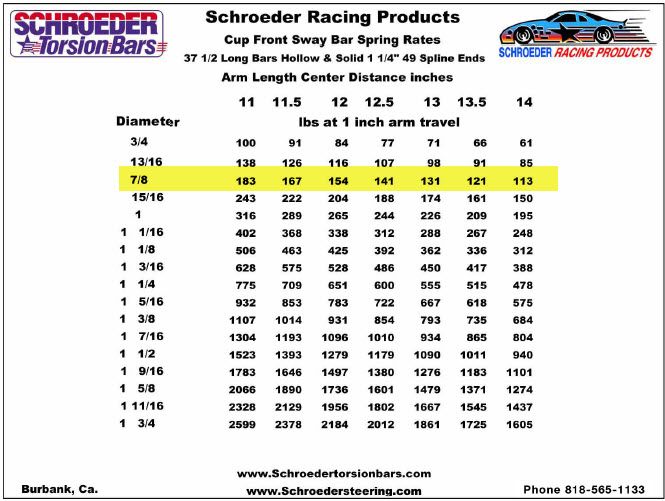

The 11/16" hexagon bar has a cross-sectional area of .409 sq.in., which is equivalent to a round bar diameter of .722"....and .722" to the fourth power = .271

The trial bar has a diameter of 1"....and 1" to the fourth power is , not surprisingly, 1

This would indicate that a bar of 1" diameter has a shear/torsional stiffness approximately 3.5 times greater than one of .722" diameter.

Have a look at this, and check the comparative figures between bars of 3/4" and 1" diameter....

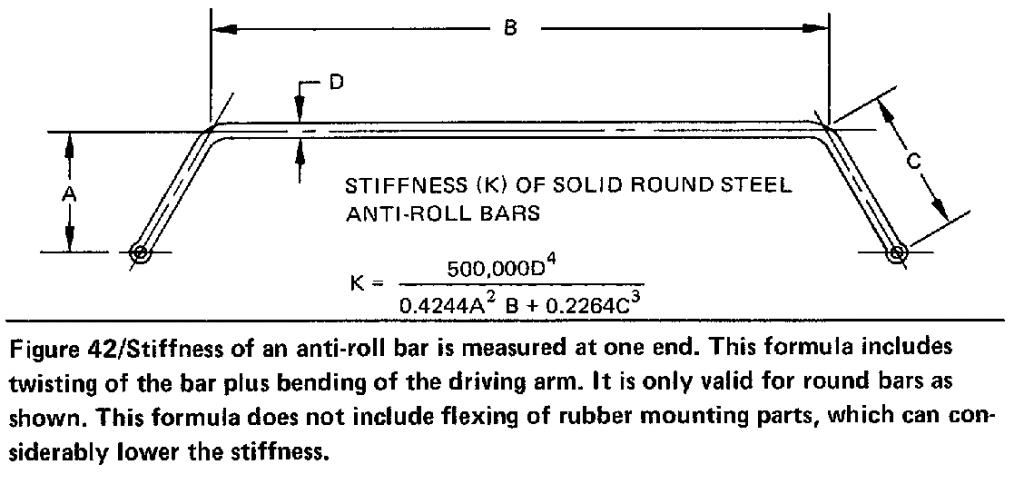

...and this, for the formula:

For our purposes, both A & C are zero.

=============================

Earlier in the thread, I said I'd keep the bar fitted to Occie until after the Bowes rally. A weeks' gone by since then, but it has been a busy one.

I'll get the bar swapped out for the original and get the trial bar off to NI for further (and more severe

Stan

vaultsman

Well-Known Member

It's fine, Rich.

Although there's some roll compared with a modern, there's definitely less than with the original but still in keeping with the car.

I'm planning to rebush the front end and check the springs next winter as I haven't touched any of these since I had Occie, so fitting the bar to a factory-standard suspension set up might give a more objective and definitive view.

As noted, Richard (quattro) does seem well pleased with the effect of his uprated bar so hopefully we're on the right lines.

Stan

Although there's some roll compared with a modern, there's definitely less than with the original but still in keeping with the car.

I'm planning to rebush the front end and check the springs next winter as I haven't touched any of these since I had Occie, so fitting the bar to a factory-standard suspension set up might give a more objective and definitive view.

As noted, Richard (quattro) does seem well pleased with the effect of his uprated bar so hopefully we're on the right lines.

Stan

rockdemon said:For our purposes, both A & C are zero.

Just an observation but if A and C where zero, K would be infinite which clearly can't be right.

vaultsman

Well-Known Member

colnerov said:I agree, A and C should be the length of the upper link arm, as that is what it's clamped to.

Colin

I agree, Colin...so my apologies to you and Pat.

The formula for the bar's polar moment of inertia is still valid, and is calculated using the 4th power of the bar's diameter.

Also, I'm assuming in all this that the trial bar's shear modulus is the same as the original.

Stan

Dave3066

Well-Known Member

pat180269 said:rockdemon said:For our purposes, both A & C are zero.

Just an observation but if A and C where zero, K would be infinite which clearly can't be right.

I think you mean that K would be undefined, not infinite. Zero is by definition nothing and you cannot divide something by nothing :wink:

....and it was Stan, not Rich who said it.

Dave

Infinity is undefined.Dave3066 said:I think you mean that K would be undefined, not infinite.

Dave3066

Well-Known Member

pat180269 said:Infinity is undefined.Dave3066 said:I think you mean that K would be undefined, not infinite.

er....no it isn't...it's infinite, which is a definition. Means limitless in size and space according to my dictionary

When have you ever heard Stephen Hawking or Brian Cox describe space as being undefined?

undefined is...without definition or unclear. Any mathematician, engineer or physicist knows what infinity is.

As I said earlier, you cannot divide something by nothing, because nothing (which is clearly defined as the lack of something) does not exist.

See what you've started Stan :wink:

Dave

colnerov

Well-Known Member

Hi, Stan, I am not a qualified Engineer so I tend to go by instinct. I must admit to having

doubts about the effectiveness of this. The centre section of the new bar having a larger

section is stiffer, the ends of the bar are the same size as before. So my questions are. Is

all the work being done by the two short ends because the have less resistance? Does the

resistance increase the more they are twisted up until just before the point they shear?

I realise that a number of people have put time, money and effort into this and I am not

knocking this, I am just curious!

Colin

edit. You lot are quicker at compiling a post than me

doubts about the effectiveness of this. The centre section of the new bar having a larger

section is stiffer, the ends of the bar are the same size as before. So my questions are. Is

all the work being done by the two short ends because the have less resistance? Does the

resistance increase the more they are twisted up until just before the point they shear?

I realise that a number of people have put time, money and effort into this and I am not

knocking this, I am just curious!

Colin

edit. You lot are quicker at compiling a post than me

Dangermouse

Member

Nice lot of bull being bandied around about maths and nothing much about how it works in real life!!

Dave3066

Well-Known Member

Dangermouse said:Nice lot of bull being bandied around about maths and nothing much about how it works in real life!!

quattro said:Mine is a 1" bar with machined 11/16" ends and it makes a remarkable difference.It cost me £200.00 a few years ago, and is worth every penny of it.Richard

That sounds like it working in real life.

pat180269 said:If you divide any number by an infinitesimally small number

Nothing is not infinitesimally small though....it's nothing.

Dave

Dangermouse said:Nothing is not infinitesimally small though....it's nothing.

Its not discontinuous either and infinitesimally small tends to zero

Dangermouse

Member

[

That sounds like it working in real life.

Dave[/quote]

Well if you have to spend £200 for it I don't call it a roaring success. I thought this was the " Custom Anti Roll Bar- Cheap opportunity! " thread, not the " very expensive for a subjective effect" thread. That is my last post on this, I've said my bit and that's that .

quattro said:Mine is a 1" bar with machined 11/16" ends and it makes a remarkable difference.It cost me £200.00 a few years ago, and is worth every penny of it.Richard

That sounds like it working in real life.

Dave[/quote]

Well if you have to spend £200 for it I don't call it a roaring success. I thought this was the " Custom Anti Roll Bar- Cheap opportunity! " thread, not the " very expensive for a subjective effect" thread. That is my last post on this, I've said my bit and that's that .

vaultsman

Well-Known Member

Dangermouse said:That is my last post on this, I've said my bit and that's that .

Thankfully.

colnerov said:Hi, Stan, I am not a qualified Engineer so I tend to go by instinct. I must admit to having

doubts about the effectiveness of this. The centre section of the new bar having a larger

section is stiffer, the ends of the bar are the same size as before. So my questions are. Is

all the work being done by the two short ends because the have less resistance? Does the

resistance increase the more they are twisted up until just before the point they shear?

I realise that a number of people have put time, money and effort into this and I am not

knocking this, I am just curious!

Colin

edit. You lot are quicker at compiling a post than me

Hi Colin,

I wouldn't profess to be a qualified Stress Engineer either, but I do remember covering such arcane topics as Torsional and Shear Stresses in Shafts when I did my HND back in the day.

However, both the maths and the experience of others (such as quattro and Graeme) would seem to support the view that a larger diameter bar (within reason) reduces body roll and improves the handling.

As far as the reduced section at either end is concerned, these are both clamped in comparatively larger masses so can (I believe) be treated as homogenous (provided the bolts stay tight!)

The acid test will come from repeated aggressive manoeuvres to determine both the benefit and whether the bar stands up to these. At the end of the day, I think it's a worthwhile project, but I won't lose any sleep if it comes to naught. If others are not convinced then it's entirely their choice whether they put their hand up or not for an uprated bar - if and when they look like being available. What I do find quite amusing is when some people dismiss the idea out of hand despite the accumulated theoretical and practical evidence out there in the real world.

I've PM'd Tim with a view to getting the bar over to him.

Cheers,

Stan

The mathematics will provide an indication, but given this is a composite bar, a spring constant for the entire bar (with the machined ends) would need to be calculated, not just that for the circular section.

The proof of the pudding etc. is in the driving. I may be wrong but I just got the impression from Stan's posts that the results were "OK" but not anything game-changing, but a re-bushing the front suspension and checking the springs were the next key items on the agenda that may when combined together provide an overall improvement?

The proof of the pudding etc. is in the driving. I may be wrong but I just got the impression from Stan's posts that the results were "OK" but not anything game-changing, but a re-bushing the front suspension and checking the springs were the next key items on the agenda that may when combined together provide an overall improvement?