Have had a busy but productive weekend. I booked the Friday off, as my wife was away for the day Saturday. This gave me two days to get my 10 bolt heads on...

DAY 1

DAY 1

Remove some stuff:

And more:

Then jacked the car up and sat it on heavy wooden blocks so I could get underneath. I had thought I could just undo the exhaust manifolds from the heads as I would on the 90, but nope - seems its easier just to lift the heads with the exhaust manifolds attached. I undid the downpipes:

Take more bits off:

Rocker covers off - its black in there, but no sign of the cornflake type things you get in really bad ones. Smelt a tad burnt, but again not terrible:

Was surprised the passenger side rocker had not been leaking more - a big chunk was missing from the cork gasket:

The rocker gear was in good shape - no up-down movement on the shafts, and the pads were perfect.

Keep going:

Cam looked ok - not knackered, but showing signs of some wear:

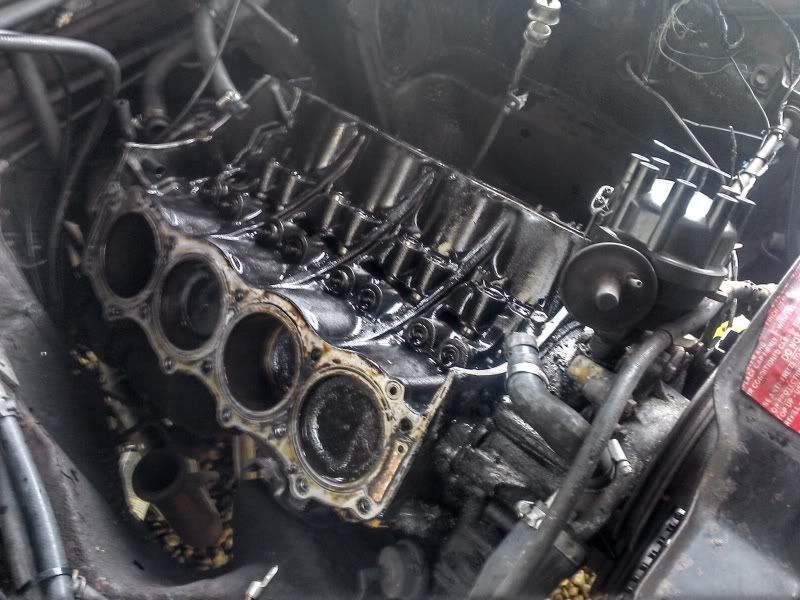

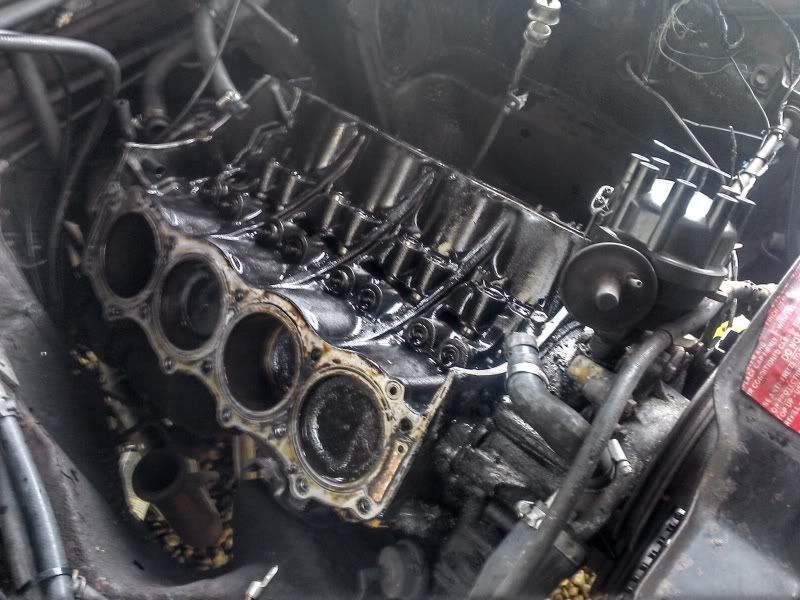

Voila! Heads off. :

Whilst I had access to it, the inner wing on the drivers side needed some paint to prevent deterioration, the existing paint was flaking off. I will revisit this when the engine comes out at some point:

Cleaned up the block faces:

DAY 2

DAY 2

P6 Head vs Discovery one, note the difference in valve sizes and the difference in chamber size due to the change in gasket type:

Nice new Ering gasket:

Heads were given one last light rub over (and i mean light) with a little scotchbrite and wd40 to remove light surface scratches from handling. They were then cleaned off thoroughly, as was the block and we end up here:

Assembly is the reverse of removal:

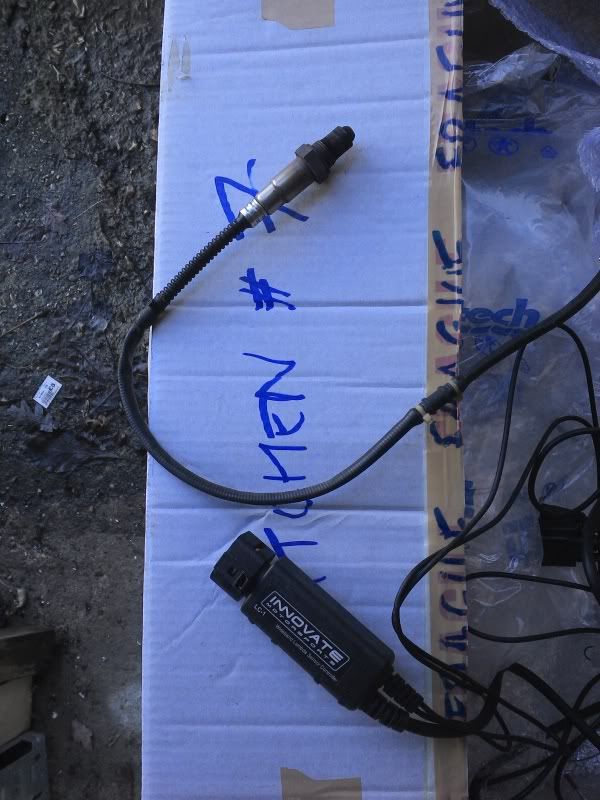

Rockers cleaned up and waxed - no idea if this will work, but I figure the cleaner and shinier something is, the harder it is for dirt to stick to it:

I then glued the cork gasket into the cover with some o2 sensor safe silicon (loctite 5910). This keeps the gasket with the cover if you remove it in the future, and generally makes fitting much easier.

The inlet manifold was degreased and cleaned off. I then fitted the new valley seals, manifold gasket and clamps and fitted the manifold itself:

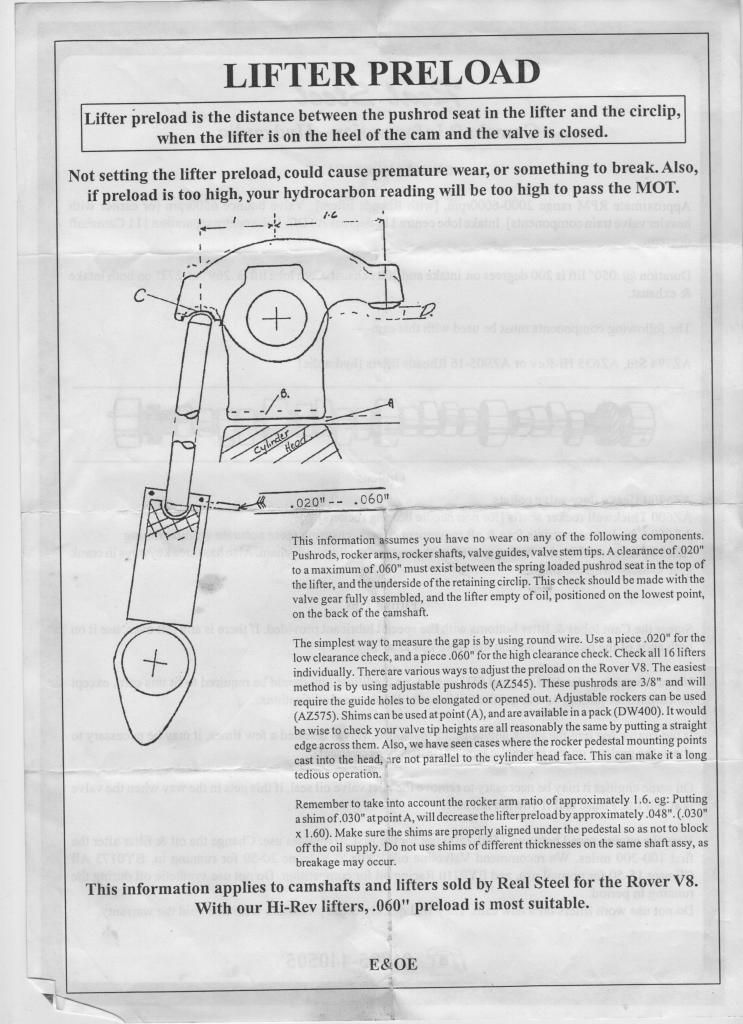

The bonnet release cable makes a handy place to keep paperwork that is being referred to:

Rocker cover gaskets were then greased and the covers fitted:

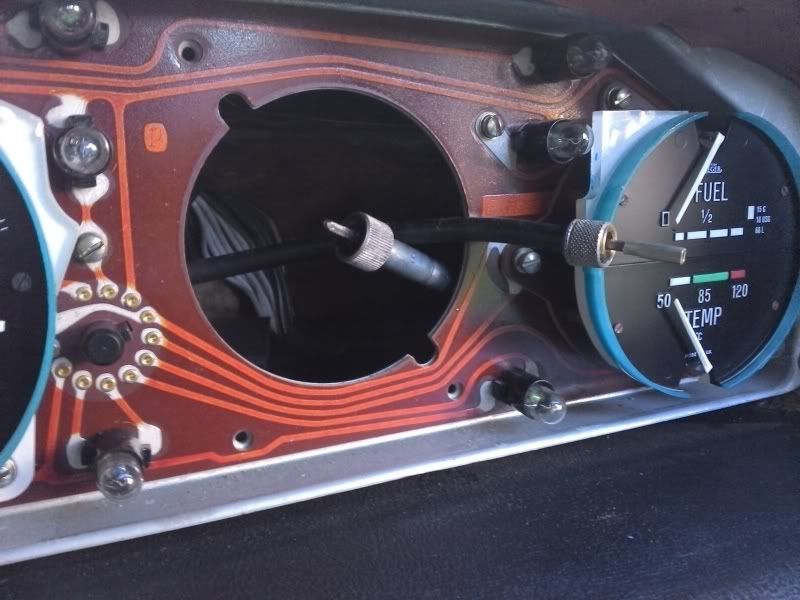

Stopped for dinner and then refitted the fuel lines, controls, , alternator, the dizzy cap and leads, the exhaust and filled it with coolant:

Turned the key and it fired up - success! But then no - the drivers side carb started dumping fuel out the overflow! :evil: :evil: :evil:

Tried giving it a whack with a mallet and block of wood, but no amount of cajoling would get it to unstick. Carb had to come off, in the process and being pretty tired at this point I managed to break the balljoint. Grrrrr! I grabbed a spare balljoint from my old manifold that was fitted to my 90. Luckily I had just popped the top off the joint and the remaining 2/3rds were enough to retain the joint ok.

I took the bottom off the carb and checked it, no visible crud or anything strange so reassembled and fitted.

This time she fired up and purred into life

I let her idle for a few mins whilst I went round checking for leaks etc, nipping up the odd water hose etc. Also waiting for the oily haze to burn off from where the manifolds have been dripped on, handled with greasy hands etc. Tense times!

All was good, and so at around 11pm I went for a quick test run around Weybridge. My Dad got back from his shift at the perfect moment, and he came with me on the voyage of discovery.

Everything worked more or less perfectly. I have a slight misfire now when you floor it in too high a gear, I expect I will need to adjust the mixture a little now that the top end is breathing slightly differently. There was a slight blow from the slip joint on the passenger side downpipe, but other than that nothing.

I then drove home to Hook (27 miles) and she didn't miss a beat.

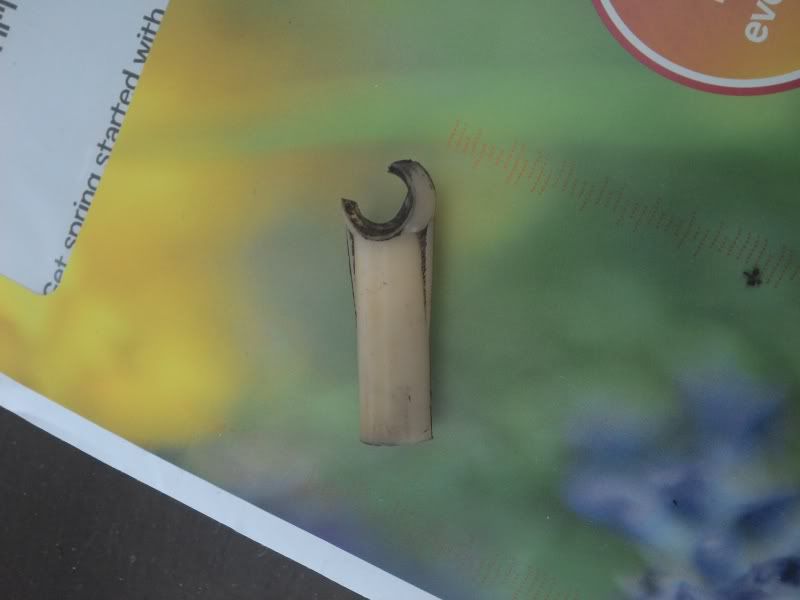

This morning I replaced the broken balljoint, and sorted the leaky exhaust joint. Balljoint below:

All back together again:

Then the wife and I went out for a very nice drive around and about in the sunshine. The car is running nicely, and seems to pull well, as long as I'm not being lazy and not changing down when I probably should. Will sort the mixture one night this week, ignition is overdue its routine tweak by now anyway so will sort that first.

Only snag I hit with fitting the ten bolt heads is that the bolt holes for ancillaries are two different sizes on the original heads. They obviously worked out in later years that drilling and tapping one size of thread would be easier/cheaper, and so you are left with bolts that are too small, and bracketry with the smaller hole sizes too. I had to source the correct larger size bolts, and drill out one of the holes on the alternator bracket to suit the larger bolt size.

Luckily we have a couple of spare v8's in the garage!