sawdustcaeser

New Member

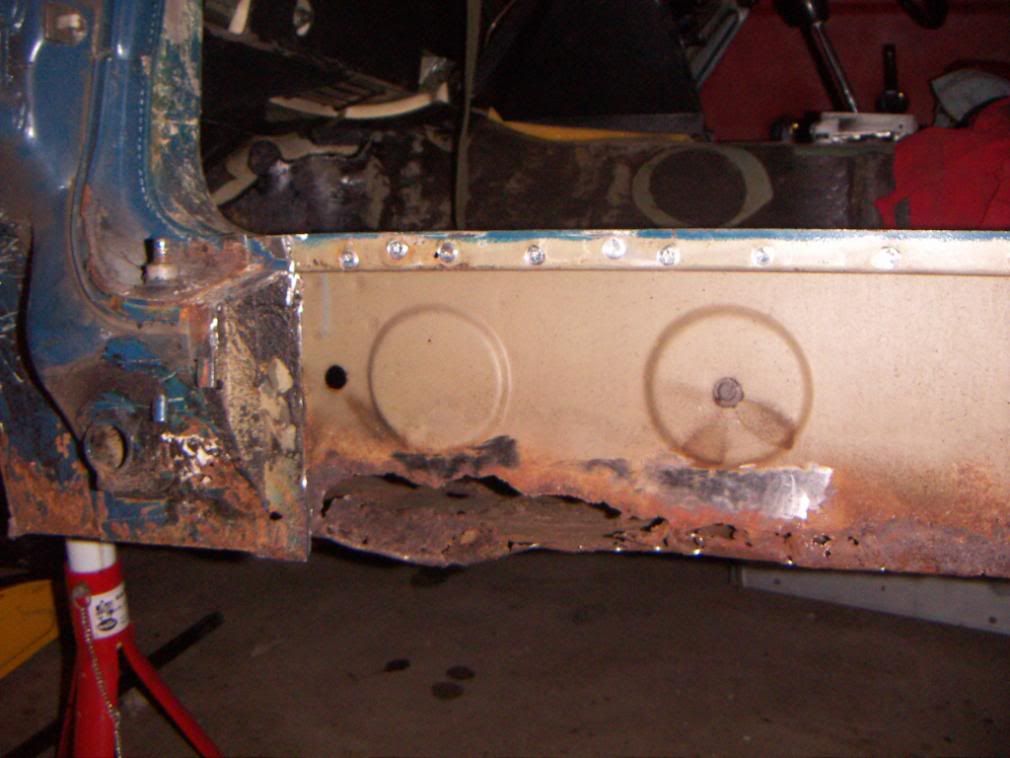

A momentous occasion! The rover base unit repairs are completed on one side. The car has been wheeled out of the garage and is now back in for work to commence on the passenger side.

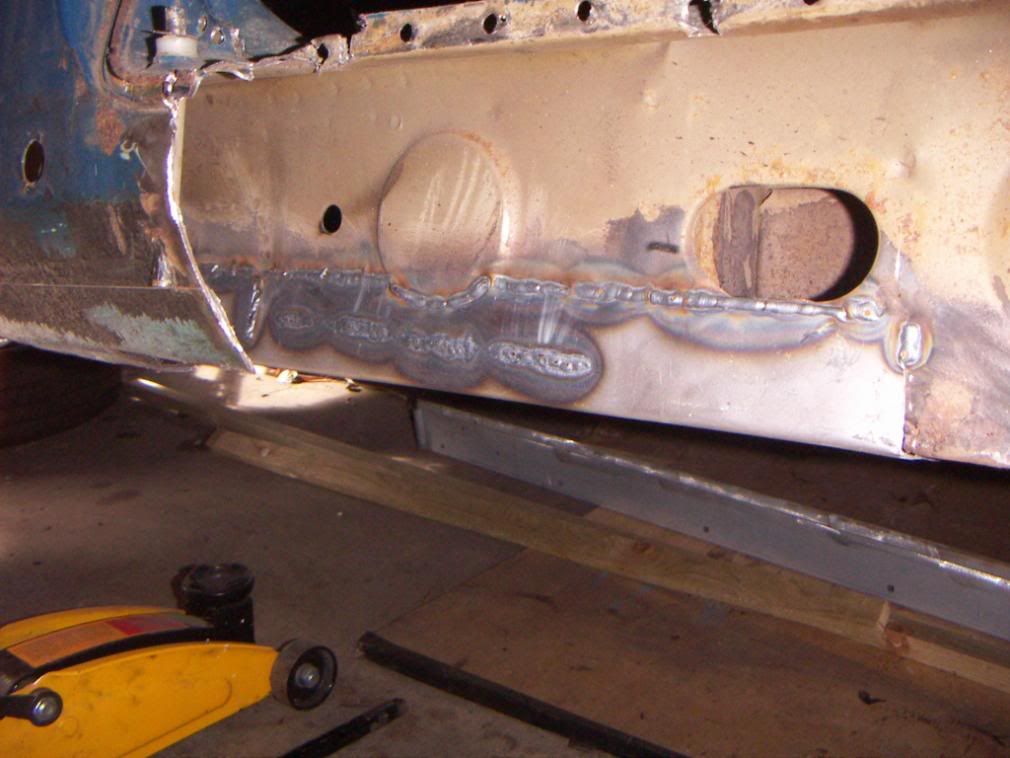

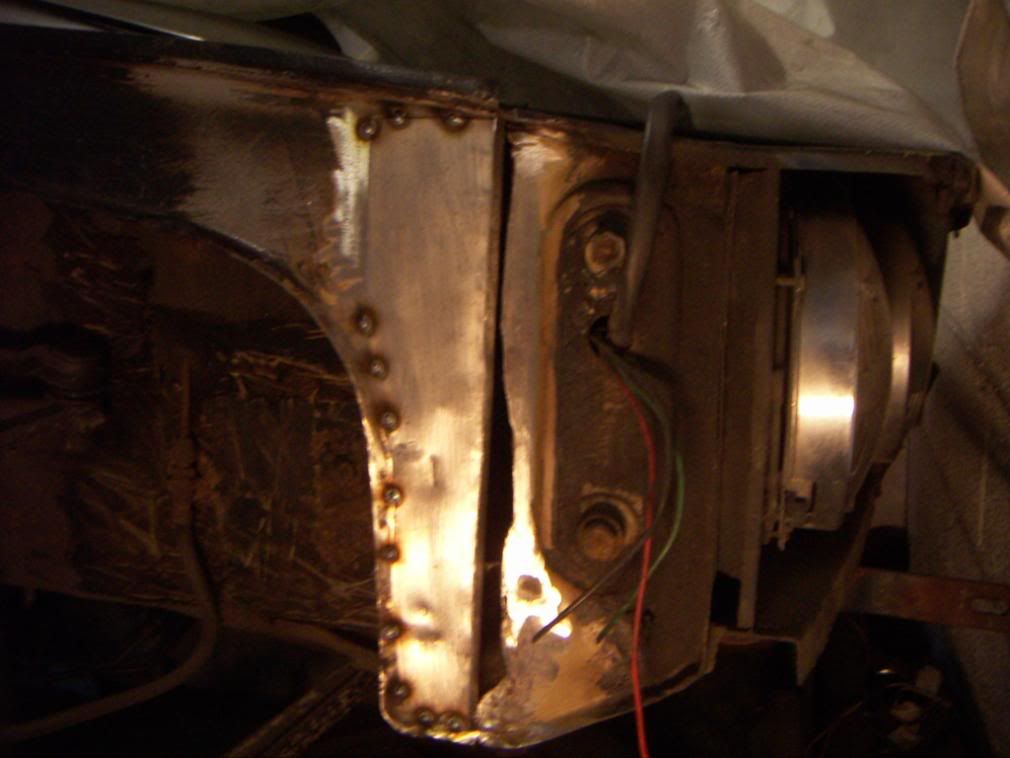

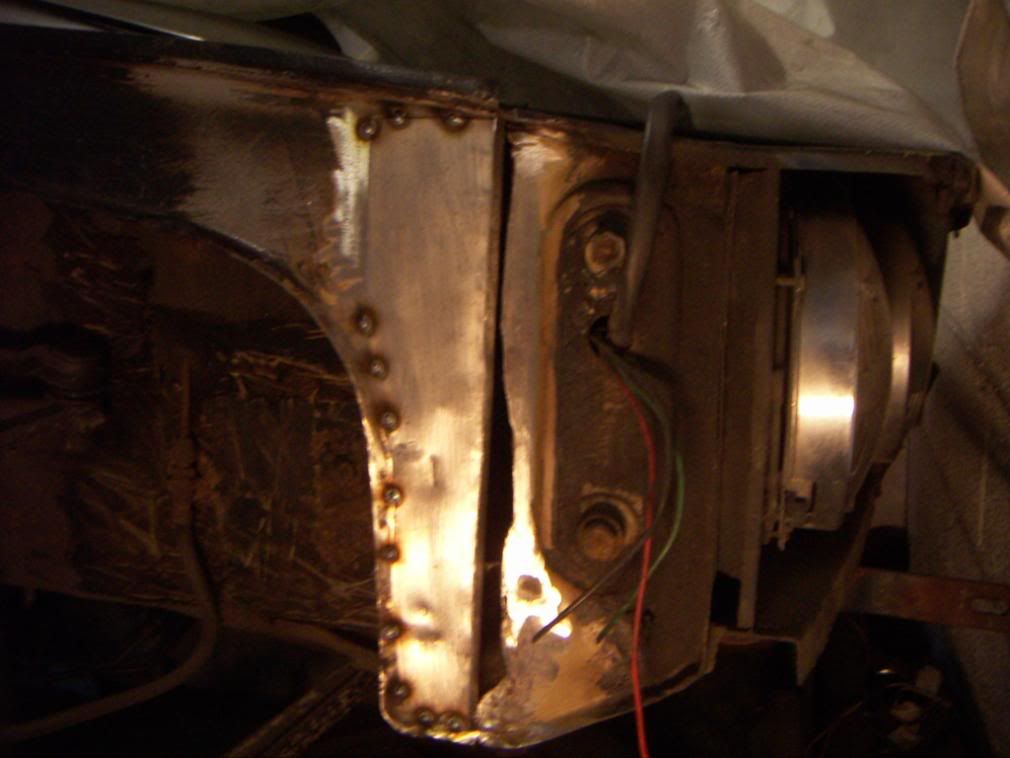

Some pictures of the repaired boot. The rusted areas were chopped out and replaced.

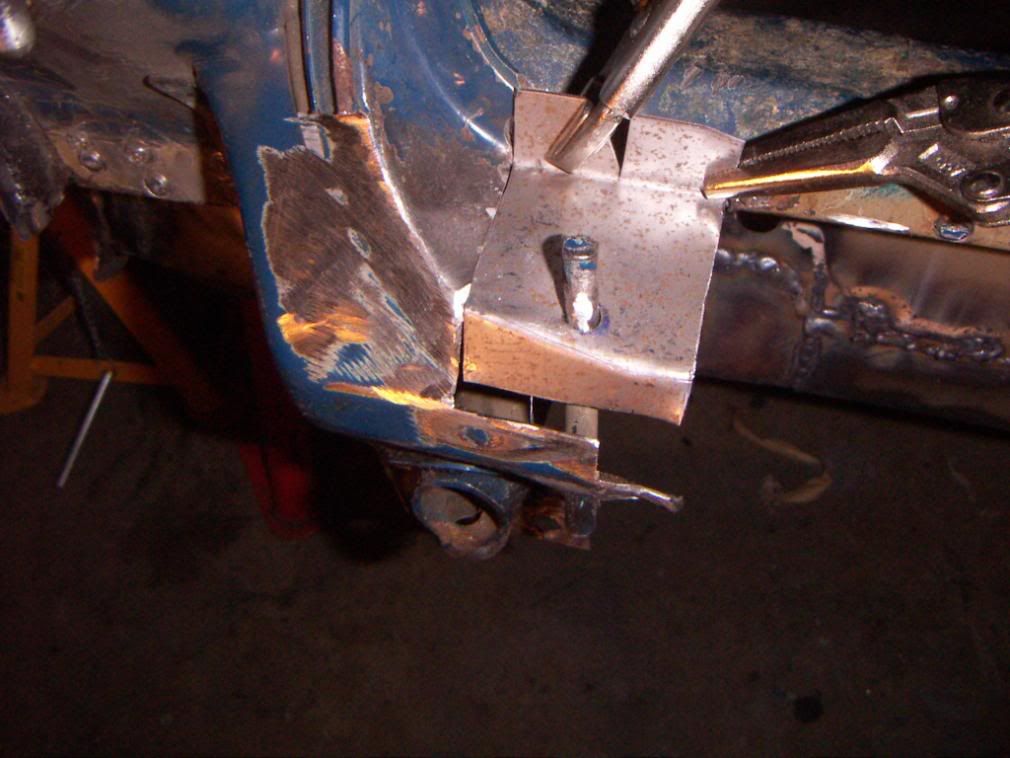

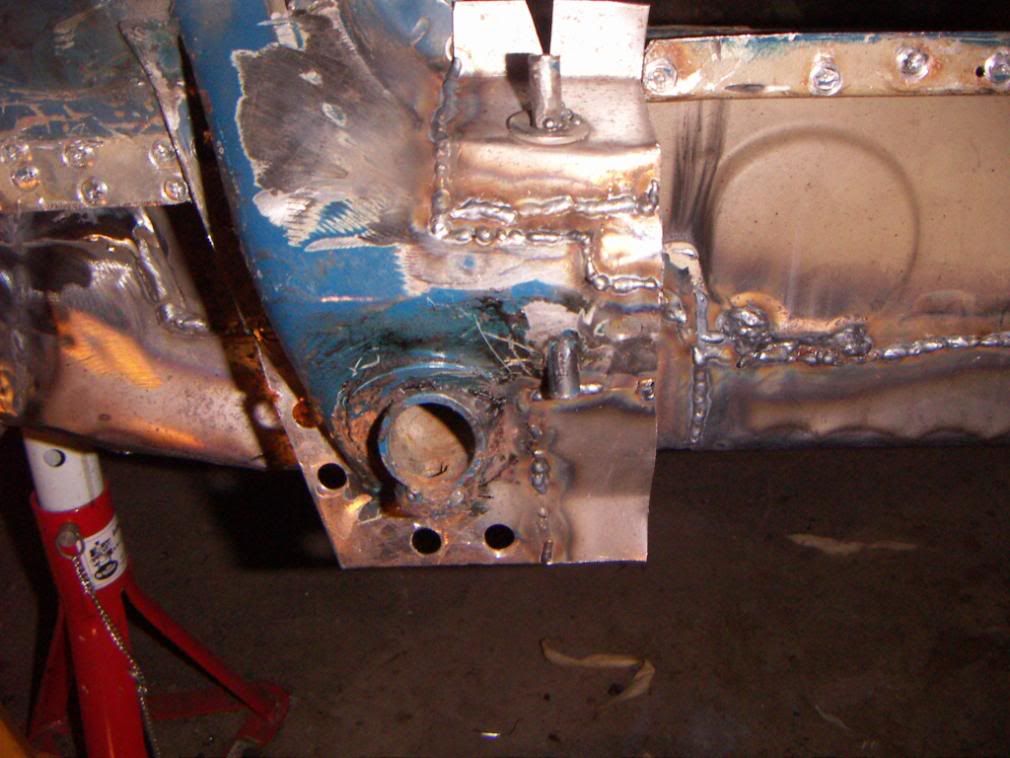

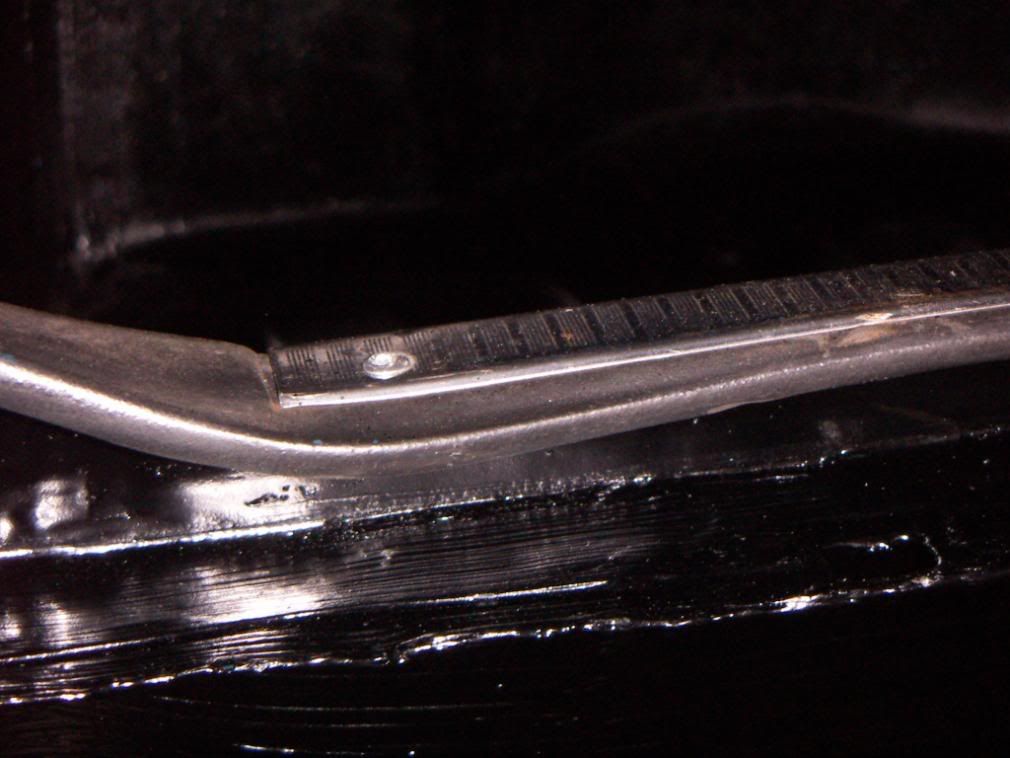

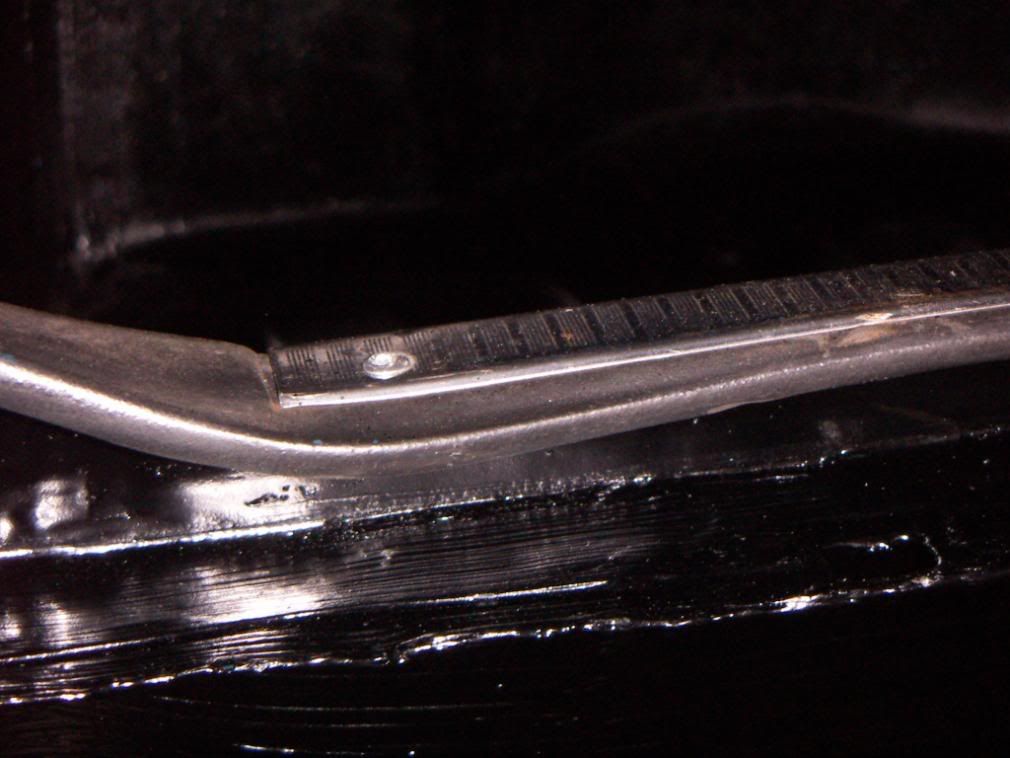

The repair to the hockey stick is also completed. I ended up chopping back even more. I repaired the area with 1 flat section on the hockey stick, and a right angled peice on the lamp cluster to try and keep the original shape.

this is the first part tacked.

My assistant has sustained a PAW15 injury!!! ( I liked that)

Some pictures of the repaired boot. The rusted areas were chopped out and replaced.

The repair to the hockey stick is also completed. I ended up chopping back even more. I repaired the area with 1 flat section on the hockey stick, and a right angled peice on the lamp cluster to try and keep the original shape.

this is the first part tacked.

My assistant has sustained a PAW15 injury!!! ( I liked that)