sawdustcaeser

New Member

As for the rest of the N/S repair.... I still haven't started on my beetle yet. I thought i'd keep going with the Rover. I have read that at some point in many resto's the owner gives up. I have to say, it is my own bloody mindedness that is keeping me going at the moment. This is my first attempted resto and I think my lack of experience, lack of remaining steel!!! and complicated composition of the vehicle have upset me

As you will remember a huge chunk of the floor was removed. The bottom 2-3 inches of inner sill removed and new steel put in.

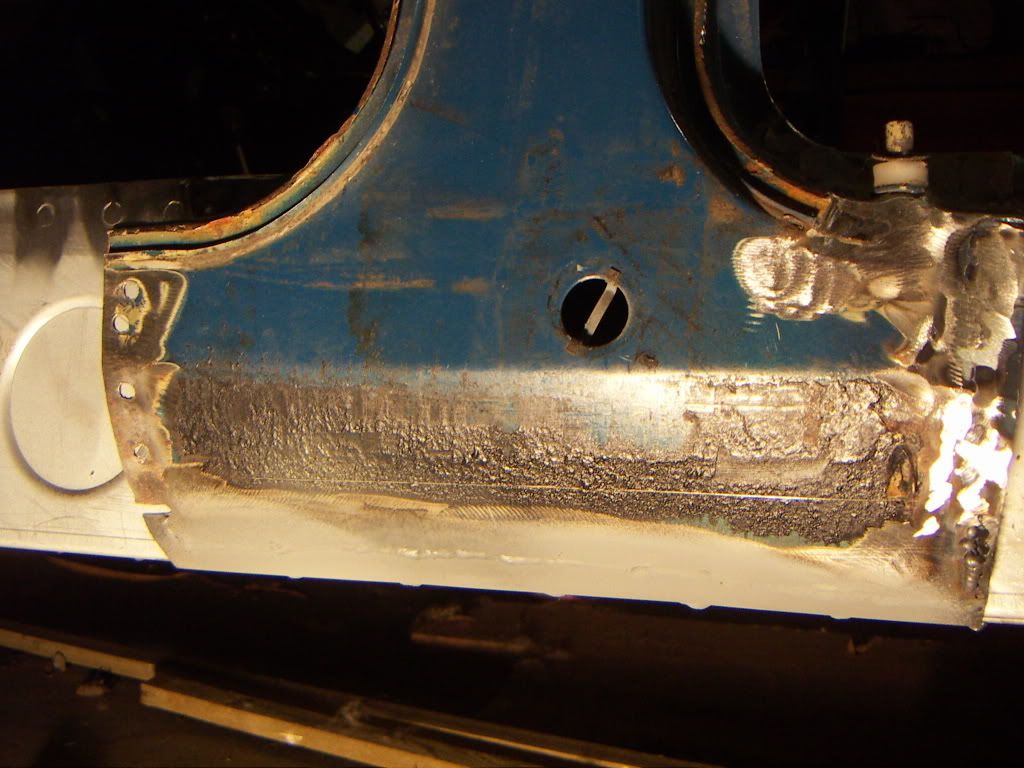

The new mid sill was then welded into place:

this is the repaired a post bottom with the new mid sill attached.

it was difficult attaching the mid sill to the underside of the inner sill because I had (foolishly) made my own repair sections in 3 peices so the line was uneven. If you see what I mean??

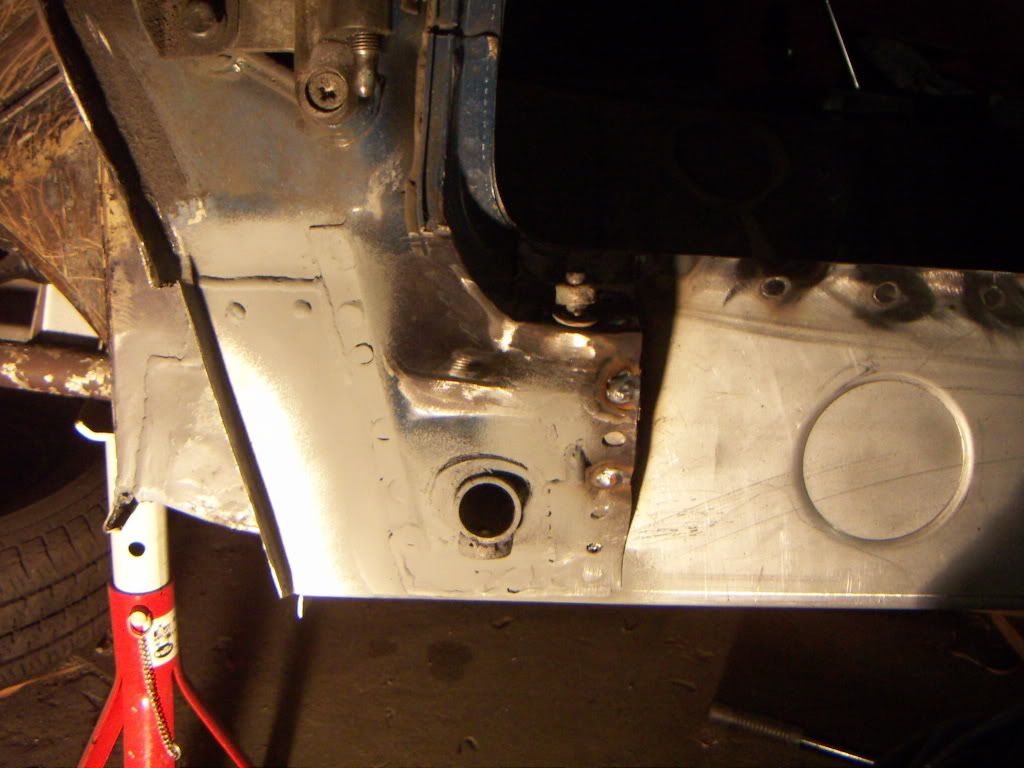

this is a view of the underside

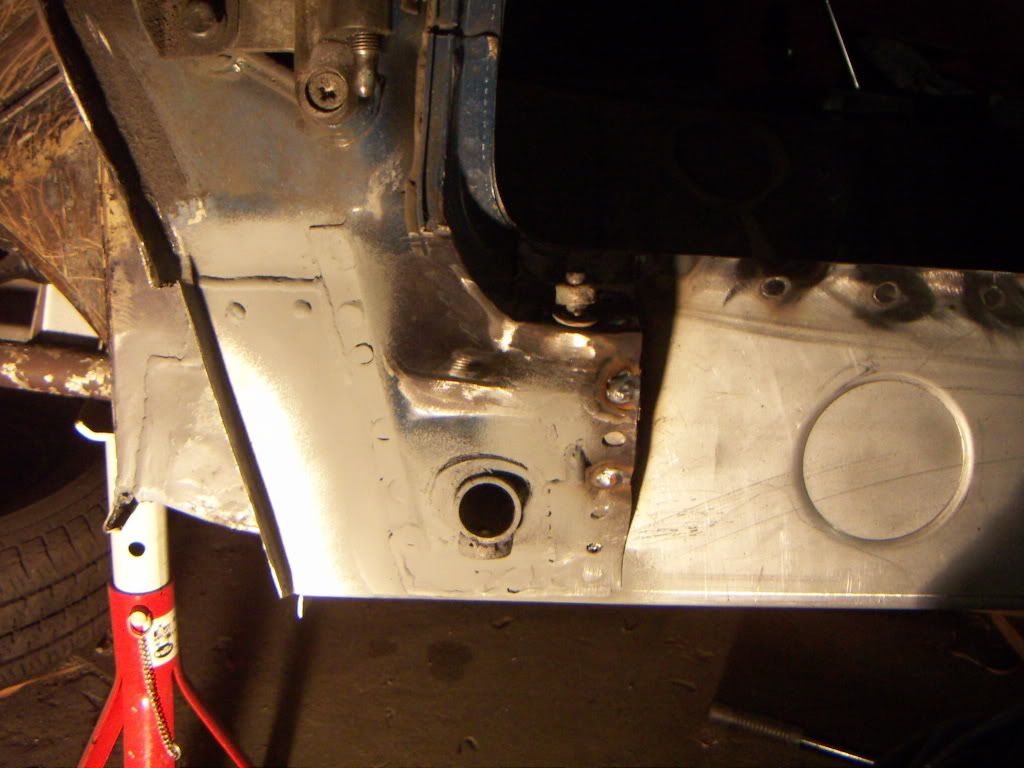

this is my exquisitley had fabricated lower d post repair section that I may need to hack off again to get to the d post internal stiffener

![color]](http://i153.photobucket.com/albums/s229/sawdustcaeser/rover%20resto2/PICT0433-1.jpg[IMG] :angry:[/color])

As you will remember a huge chunk of the floor was removed. The bottom 2-3 inches of inner sill removed and new steel put in.

The new mid sill was then welded into place:

this is the repaired a post bottom with the new mid sill attached.

it was difficult attaching the mid sill to the underside of the inner sill because I had (foolishly) made my own repair sections in 3 peices so the line was uneven. If you see what I mean??

this is a view of the underside

this is my exquisitley had fabricated lower d post repair section that I may need to hack off again to get to the d post internal stiffener

![color]](http://i153.photobucket.com/albums/s229/sawdustcaeser/rover%20resto2/PICT0433-1.jpg[IMG] :angry:[/color])