The day had arrived for the original 1974 factory fitted Speedo cable and casing to be replaced in its entirety. The casing was noticeably damaged in a number of places between the right angle drive at the transmission and where it entered the tunnel.

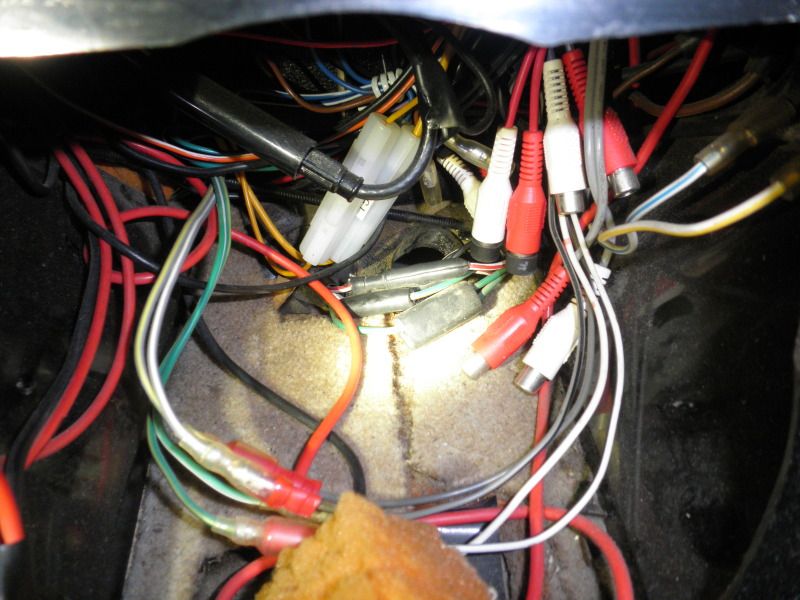

So I started by removing the speaker panel, although a speaker no longer resides within.

The original cable can be seen passing through a rather tired grommet.

I moved the instrument panel forward and angled to the side so as to allow removal of the casing from the Speedo’s right angle drive. I also removed the glove box as it provides easier access for both removal and refitting.

Old cable.

The original casing attached to the right angle drive on the transmission.

With the casing disconnected at both ends, I withdrew it through the tunnel bringing it inside.

The grommet needs to be replaced. As I didn’t have a spare, I packed around the new casing with a suitable length of foam rubber.

The casing noticeably damaged.

With new and old together, the latter I had purchased some years ago from S & G.Walker was a little longer overall.

New along side old.

The original foam sleeve was also becoming quite fragile, so rather than removing it altogether I covered it with a layer of bubble wrap that had its own plastic backing.

Wrapped nicely

This I hoped would provide insulation from any unwanted noise along with protection of the casing against possible damage from scuffing.

New casing in place.

With the casing in place and attached to the right angle drive on the transmission, the cable was fed through at the Speedo end, lubricated with Castrol EPL-2 as it went. I chose this grease for its high temperature resistant characteristics.

I noted that the new casing’s attachment nut didn’t appear to go on as far or indeed had not gone on as far as it should, at the transmission’s right angle drive. There was no float in the casing, but to be sure I measured the width of both new and old.

New casing in place

Attachment nut on original casing, width noted.

The attachment nut on the new casing is not as wide.

I observed that the old casing, once left hanging up prior to disposal, had been dripping a little transmission fluid. I had always used grease on the cable, so I am not able to say with certainty how this fluid had managed to enter the casing.

I am not entirely certain, but the lower section of the right angle drive on the transmission appears to have been changed, and this, had it taken place, would have occurred at the last rebuild in 2009. I could see no evidence of transmission fluid leaking from it, so where the little drop that sits on the bolt that secures the drive to the transmission originates from, I cannot say.

Road testing revealed a beautifully quiet operation in addition to a very still Speedo needle function. With the old cable and casing, the Speedo needle wandered at least 5mph (8kph) about the desired speed, so this was a marvellous improvement.

Ron.