danm

Member

PeterZRH said:Fascinating thread. Great pictures. Reminds me what a spectacular lack of effective soundproofing a P6 has on the bulkhead compared to a modern despite the inch-thick carpets.

Cheers mate!

I had a little delivery today

The first job was to remove the flange plate.

It was then offered up to the engine to see if anything would line up or not....unsurprisingly, not a lot did.

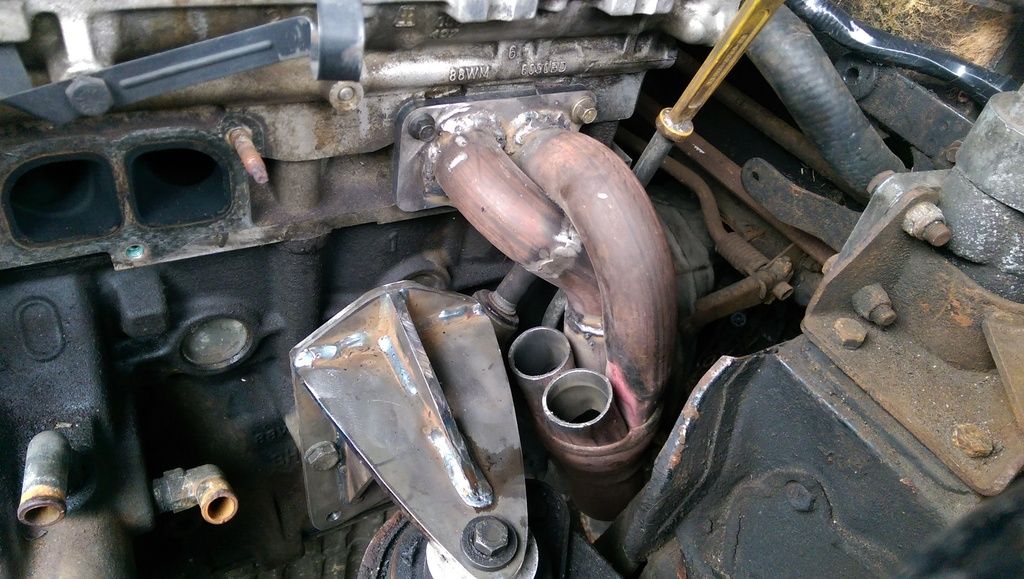

Three if the primaries were cut off just above the collector, the new manifolds original No2 runner is now my No4, it was offered up and then tacked onto the flange.

A view through the collector, I have angled it back slightly, there is enough room for a single down pipe to pass between the NS chassis rail and gearbox.

I cut and shut one of the other primaries to create a runner for N03, this was then welded up leaving me with this.

I have a couple of bends left but I am short of suitable pipe, hopefully I will be able to find a supplier tomorrow so that I will have the primaries finished leaving only the

down pipe to do. Runners 1+2 will be a fair bit more awkward than the ones that I have done, still I am pleased to be as far on with this as I am.

Dan